Ansys and EOS collaborate to advance AM workflow

October 24, 2020

Ansys, Pittsburgh, Pennsylvania, USA, a provider of engineering simulation software, is collaborating with EOS GmbH, Krailling, Germany, to provide an enhanced, streamlined workflow for Additive Manufacturing.

The new workflow pairs EOS’ metal AM machines with Ansys’ simulation solutions – allowing Additive Manufacturing engineers to develop highly-precise parts, improve productivity, reduce production time and deliver new products faster.

Ansys explains that AM adoption is accelerating across many industries, but many engineers continue to use a trial-and-error approach and optimised process parameters for developing their desired geometries, which is quite expensive. Build failures result in reduced efficiency, increased development costs and a slower time to market. Together, EOS and Ansys are helping engineers determine and mitigate build failure issues prior to the build process, enabling parts to be generated faster and more accurately for customers.

As a member of the EOS Developer Network, Ansys will enhance user AM processes via Ansys simulations, and expedite builds by sending jobs directly to EOS’ AM machines. Additionally, to enhance simulation fidelity, Ansys simulations will integrate EOS-specific data using EOS’ open-source application program interfaces.

This integration will help improve part geometries by predicting and compensating for distortion and other issues to significantly reduce build failure and upgrade manufacturing processes to increase productivity. It will also improve material property selection by forecasting how design changes will affect the microstructure of parts. With the new workflow, user-designed, complex build jobs are expected to be up to 20% faster and simple jobs up to 50–60% faster than possible by previous methods.

“EOS and Ansys are transforming how companies worldwide design parts, enhance products and create leading-edge inventions,” stated Martin Steuer, senior vice president, Division Software at EOS. “Combining Ansys simulations with EOS 3D printing technology creates a seamless workflow that enables our mutual customers to reduce spending, increase reliability, boost efficiency and deliver products to market much earlier than the competition.”

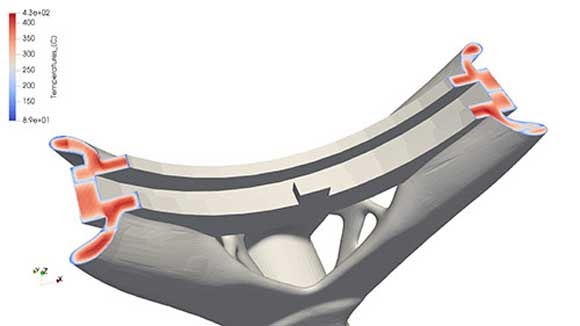

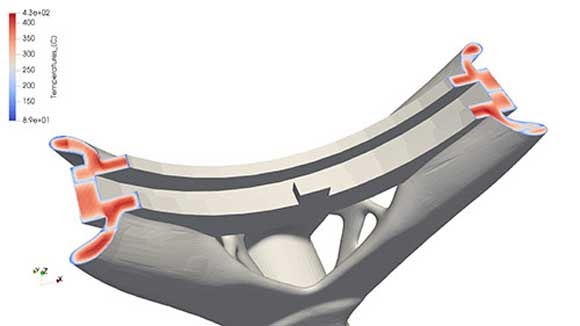

Shane Emswiler, senior vice president at Ansys, commented, “Leveraging EOS scan vectors, Ansys simulations calculate and predict issues such as porosity, residual stress, thermal distortion and help users avoid potential blade crashes. This collaboration provides new levels of insight to users, making it easier for them to build complex parts more precisely.”

Emswiler continued, “Uncovering these issues early using simulation empowers engineers to select the correct parameters and understand if a part can be built as-is or must be redesigned – ultimately greatly minimising the number of builds by substantially reducing trial-and-error failures, resulting in reduced material waste and substantial cost savings.”