AM leaders agree to establish Bavarian AM Cluster

October 13, 2022

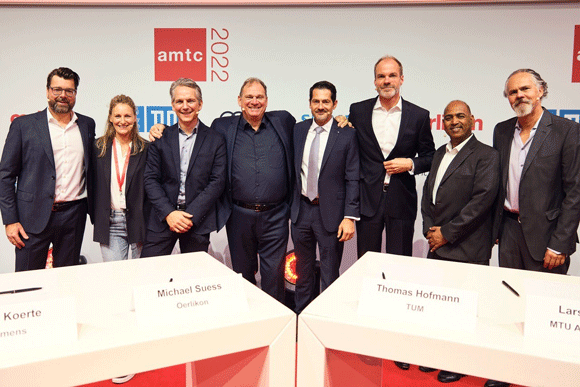

Oerlikon Group, Pfäffikon, Schwyz, Switzerland, has announced that seven companies and the Technical University of Munich (TUM) have signed a Memorandum of Understanding during the AMTC conference which will see the establishment of the Bavarian AM Cluster (BAMC).

The founding companies, which include Audi AG, EOS, GE Additive, Linde, MTU Aero Engines, Oerlikon and Siemens and the TUM, have agreed to establish BAMC as a non-profit association in spring 2023.

The aim of BAMC is to facilitate close consortium cooperation between companies and the university in order to overcome technical and economic challenges on the way to the industrialisation of Additive Manufacturing.

The members of the cluster decide on research priorities and projects that are implemented jointly or as part of research contracts with TUM. In addition to initiating new integrative research and development approaches, the cluster also aims to establish partnerships with other commercial enterprises and academic partners, develop innovative education and training concepts and launch lighthouse projects to demonstrate the benefits of Additive Manufacturing.

Unique to this cooperation is the close proximity of all partners and institutions to each other as the association’s premises will be located on the Garching campus in the same building as those of the relevant chairs at TUM, as well as those of the TUM-Oerlikon AM Institute. In the building on the TUM Campus Garching, teaching, research and development are carried out on around 10,000 m2 and transferred directly to the production of technologically advanced products.

The special feature here is that the university and the company conduct research together under one roof. This is intended to lead to maximum efficiency through the mutual provision of research infrastructure and knowledge exchange. Currently, final construction activities are taking place so that the Chair for Materials Technology of Additive Manufacturing (Prof Mayr), the Chair for Laser-based Additive Manufacturing (Prof Wudy), the TUM-Oerlikon-AM Institute, Siemens and Oerlikon can move into the building promptly.

“With the Bavarian AM Cluster, the industry in Bavaria is clearly preparing for the future,” stated Prof Michael Süss, executive chairman of Oerlikon. “In addition to the AMTC congress and the AM Institute founded in February between Oerlikon and TUM, this is the third initiative for joint cooperation for the industrialisation of AM that we are launching. I am convinced that with the cluster, we are taking a decisive step towards the full integration of additive manufacturing into the industrial process.”

Prof Thomas Hofmann, president of TUM, commented, “With the AM Cluster, we are further expanding research and development activities in the field of Additive Manufacturing here in Munich, thus maintaining Bavaria’s leading position in this technology field.”

Dr Ami Gupta, Vice President Technology at Linde, added, “Linde has long been a pioneer in innovations to manufacturing processes that enable customers to achieve cost reduction, productivity and sustainable development. As Additive Manufacturing begins to revolutionise the way in which objects are produced, we are proud to be collaborating with other leading innovators to contribute our unique knowledge in gases and leading-edge technologies to apply them effectively.”