AlphaSTAR adds metal Additive Manufacturing simulation tool to GENOA 3DP

February 8, 2018

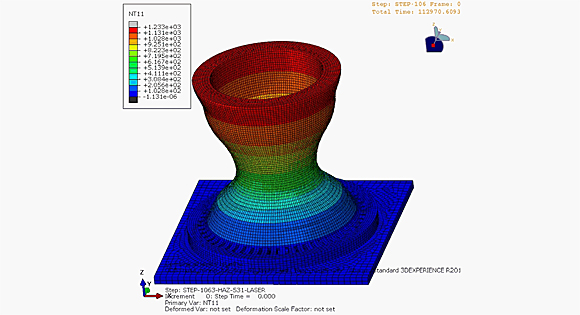

Using multi-scale progressive failure analysis methods to replicate the entire AM process, GENOA 3DP is reported to be able to determine voids, cracks and other manufacturing anomalies (Courtesy AlphaSTAR)

AlphaSTAR Corporation (ASC), Long Beach, California, has released an update to its Additive Manufacturing Simulation Tool, GENOA 3DP, which adds metal Additive Manufacturing simulation capabilities. GENOA 3DP is said to allow users to accurately predict deformation, residual stress, damage initiation and crack growth formation associated with as-built AM parts.

Using multi-scale progressive failure analysis methods to replicate the entire AM process, from material characterisation to advanced structural analysis, GENOA 3DP is reported to be able to determine voids, cracks and other manufacturing anomalies. Additionally, the tool provides end users with the ability to import a G-Code file, generate a structural mesh, run test validated analysis and optimise the AM build.

With the cooperation of industry partners, GENOA 3DP has reportedly be tested and verified through real life tests from the beginning to the end of metal AM product life cycles. The updated tool offers the following capabilities:

- Process simulations: high fidelity and low fidelity solutions for thermal and thermal-structural analysis

- Automatic mesh generator from g-code

- Automatic and external mesh am model generation

- Environmental effects (e.g., oxidation) on material properties

- Scatter and uncertainty prediction

- Void and damage calculation using global/local material modelling with grain and grain boundary approach

- Post-build simulation; bottom plate removal

- Qualification and certification: as-built part performance prediction

The ASC team states that it has been working over the years to ensure GENOA 3DP’s metal capabilities match the existing toolset for polymeric materials. “We are very excited to introduce this product to the metal Additive Manufacturing market and make it available for real industry use,” stated Kay Matin, ASC President. “The toolset has the potential to revolutionise the way engineers alike solve their AM challenges.”