Ai Build looks to expand into US following $8.5 million Series A funding round

October 19, 2023

Ai Build, an Additive Manufacturing software company based in London, UK, has raised $8.5 million in a Series A round led by IQ Capital, with participation from Nikon as a strategic investor, as well as existing investors Superseed, ACT Venture Partners, Atlas Ventures (UK), and Seedcamp.

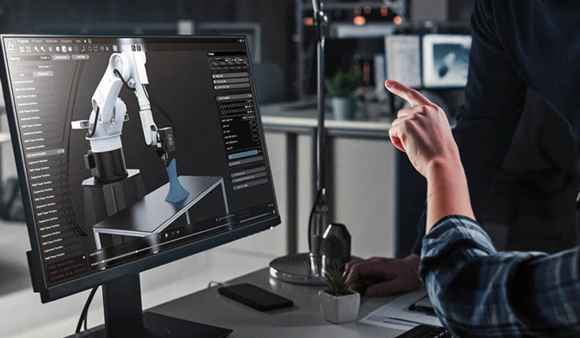

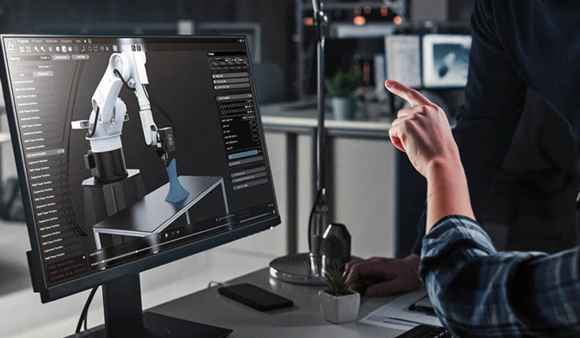

Ai Build was established in 2015 by two architects, Daghan Cam and Michail Desyllas. The company offers manufacturers a cloud-based solution designed to reduce costs, lead times, and material waste in the Additive Manufacturing process.

Daghan Cam, Co-founder and CEO at Ai Build, stated, “Despite its clear economic and environmental benefits, manufacturers have difficulty implementing Additive Manufacturing at an industrial scale. This is due to concerns about its reliability and ease of adoption. We believe that automation and smart use of data is the solution to this problem. By partnering with Nikon as a leading technology provider who has a grand vision for the future of manufacturing, and IQ Capital as a deep-tech investor with proven track record of supporting global businesses, we are well positioned to achieve our goal for automating the factories of the future.”

Ai Build collaborates with major manufacturing firms, such as Boeing, to expand the use of Additive Manufacturing in large-scale industrial applications. These applications encompass specialised tooling and end-use components in the aerospace, automotive, and energy sectors. Early adopters of Ai Build have witnessed significant enhancements, including a 65% reduction in failed production attempts and a 90% increase in overall build efficiency.

As Ai Build incorporates additional machines, users, and manufacturing data into its platform, the system’s capabilities and level of automation continue to grow. The company’s objective is to eliminate all inefficiencies resulting from human error, thereby simplifying the manufacturing process, making it more intelligent, sustainable, and cost-effective.

“Ai Build offers extensive solutions that enable automated workflows, bringing efficiency and sustainability to the field of AM. In tandem with Nikon’s capabilities, together we will deliver innovative solutions that revolutionise AM,” Yuichi Shibazaki, Corporate Vice President and Officer in charge of Next Generation Project Division at Nikon, contributed.

Ai Build plans to utilise the funding to expedite its product roadmap, enabling the company to onboard a larger customer base with enhanced levels of automation and AI capabilities. The investment will also facilitate the expansion of Ai Build into North America through the establishment of a subsidiary in the US, as well as the continued growth in Europe. Furthermore, the engineering teams of Ai Build and Nikon will collaborate to push the boundaries of Additive Manufacturing by leveraging their expertise in software and hardware technologies.

Download Metal AM magazine