AddUp launches project to expand use of Additive Manufacturing for injection moulding applications

January 29, 2024

AddUp’s Tooling Competence Centre, located within the WBA Tooling Academy in Aachen, Germany, has announced the launch of the 2024 Additive Manufacturing for Injection Molding project focused on developing and implementing innovations using Additive Manufacturing for injection moulding applications.

The year-long project includes seventeen industrial companies and is supported by a consortium of AddUp’s AM experts and partners. The project aims to focus on seven critical areas that are important for tooling manufacturers. Every month, AddUp and one of their partners will present challenges and innovations for one of these focus areas; develop solutions, AddUp will create samples, benchmarking parts, as well as production moulds. Vigorous testing and data collection will be prepared and published at the end of the project.

The goal of the project is to educate the tooling industry about the advantages of Additive Manufacturing, which can lead to improved productivity, quality, safety, and sustainability. The seven focus areas for this project include:

- Tool steel development

- Productivity

- Quality

- Time savings

- Functions

- Sustainability

- Work safety and powder handling

AddUp has enlisted a consortium of AM experts to guarantee the best support. AddUp partners committed to this project include Swiss Steel Group (SSG), Siemens AG, Fraunhofer Institute or Laser Technology (ILT), AZO, Hotset, The Institute of Plastics Processing (IKV), 3D Laser BW, Herding GmbH, Air Liquide, IwF, Härtha Group, AZL Aachen GmbH, Ingenieurbuero Juri Muller (IBJM), IPG Laser GmbH, Aachen Center for Additive Manufacturing (ACAM), WBA Tooling Academy and Novanta Europe GmbH.

Tooling manufacturers are invited to participate by bringing their own challenging tooling applications for evaluation and optimisation. However, an existing application is not required, for example, if confidentiality guidelines do not permit. Companies that are exploring Additive Manufacturing solutions for their injection moulding applications are also encouraged to join. Each member is expected to actively participate in the monthly meetings, provide feedback, and collaborate with other participants.

The project will begin in the first week of February with a meeting hosted by AddUp’s partner, Siemens AG, at their facility in Erlangen, Germany. Monthly workshops will be held from March to September, and the results and data will be presented in November.

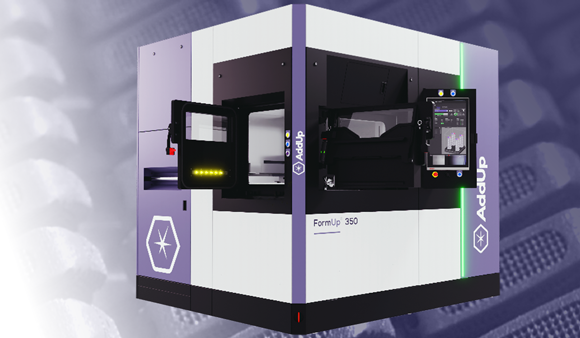

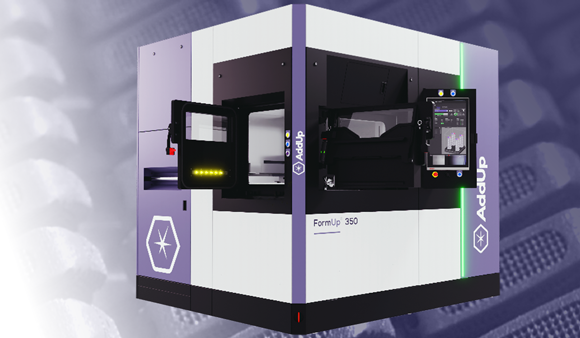

The Tooling Competence Centre serves as AddUp’s German subsidiary and is equipped with a FormUp 350 Laser Beam Powder Bed Fusion (PBF-LB) machine. The centre provides a resource for tooling manufacturers to validate their applications and partner with experts in PBF-LB technology.

Download Metal AM magazine