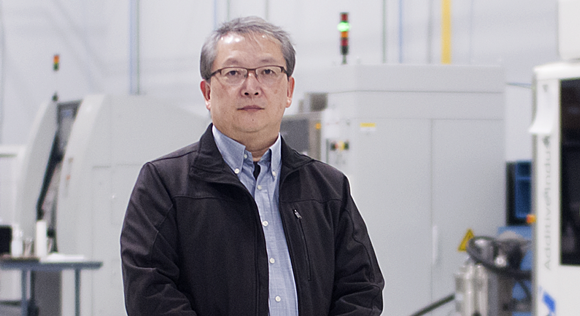

Addman hires Dr Youping Gao in new Tech Chief Scientist & EVP role

February 2, 2022

Addman Engineering, headquartered in Bonita Springs, Florida, USA, has appointed Dr Youping Gao to the newly created position of Chief Scientist and executive VP of Technology, a position which is said to highlight the company’s commitment to space and hypersonic applications.

“As a twenty-five year veteran of Additive Manufacturing in the space industry, I believe we are living during a convergence of scientific and industrial capabilities that Addman is harnessing to yield incredible results for our customers,” stated Doctor Gao.

Dr Gao has been recognised by commercial and defence entities for his knowledge of alloys including niobium, copper, and high strength aluminium. Dr Gao spent twenty-one years at Aerojet Rocketdyne with its advanced propulsion manufacturing capabilities. Gao is a Fellow of the Laser Institute and, in that role, led the AM development effort that was said to be the first in the US to achieve NASA certification for AM production of mission critical components for manned spaceflight.

Joe Calmese, Addman CEO, commented, “Adding Dr Gao to our staff is an honour. Beyond his experience in the space industry, and his long track record of innovations in additive, we’re most excited about Dr Gao’s commitment to teaching others and serving the industry in exciting new ways.”

“Our partners want us to solve the most important and complex manufacturing challenges of our time,” he continued. “Our partners want us to have a team of world class engineers, scientists, and manufacturing professionals to deliver mission critical products when they need it – and where they need it. Addman’s expansion in California gives us the proximity to our partners to enable the near real time innovation that is needed to move our industry forward.”