Additively manufactured electric motor offers increased power and less material usage

July 20, 2023

Researchers from the University of Sheffield, UK, and collaborators at the University of Wisconsin-Madison, USA, have built an electric motor using Additive Manufacturing technology. It is claimed this development could pave the way for future electric motors with increased power, while using less material.

The prototype, which uses a higher-percentage silicon electrical steel that reduces energy losses, was designed as part of a collaboration between Alexander Goodall, a doctoral student in the Department of Materials Science and Engineering; UW-Madison post-doctoral research assistant FNU Nishanth and their advisors, Professor Iain Todd and Eric Severson.

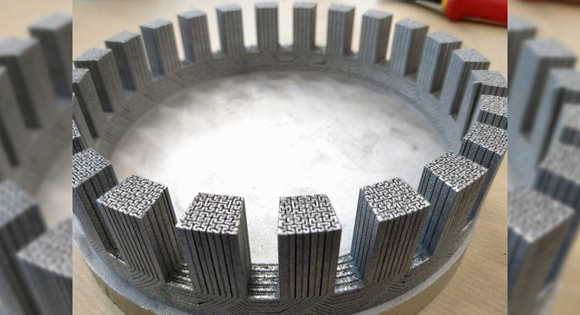

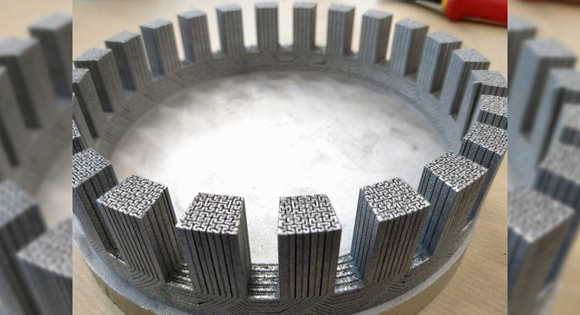

The motor design consists of a stator, a circular-shaped object with prongs that wires can be wrapped around to create a magnetic field. It is hear that the biggest difference between this prototype and traditional stators can be seen, with the prongs themselves featuring an intricate design of thin geometric lines meant to reduce energy loss.

The collaboration started when Goodall and Nishanth met at a conference in 2020. Together, they realised that Sheffield had access to the Additive Manufacturing technology that could make UW-Madison’s unconventional motors a reality. Goodall came up with the concept, designed, developed, and manufactured the stator, whilst researchers at the University of Wisconsin completed comprehensive testing, showing an improvement in torque density.

When the additively manufactured prototype was tested in October 2022, it was found that it was giving more torque than they thought was possible with less material.

“When you have 30% lower mass, you would expect that your torque would also be lower… but that wasn’t the case,” Nishanth explained. “So, this shows that you know you’re actually going to net torque density improvement in this machine and if we can further improve this (making a more efficient motor), it would be a game changer.”

Traditional methods of creating stators in electric motors use a lamination process, wherein sheets of electrical steel are stamped out. The result is a stator stacked with the laminations with tiny but visible ridge lines on the top of the prongs.

That method, though easily replicated, tends to rely on using an electrical steel alloy with 3% silicon in it, which lends to higher rates of energy loss and less efficiency. An electrical steel alloy made with 6.5% silicon, recommended by the US Department of Energy, reduces energy losses but is more brittle and is less likely to withstand the traditional lamination process.

However, Additive Manufacturing eliminates the need for tons of pressure to be exerted during rolling and the machine can print the delicate pattern on the small 10-kilowatt prototype stator within twenty hours. While that wouldn’t be enough energy to run an electric vehicle, the model could be easily scaled up to reach 40 kilowatts and additively manufactured faster on an industrial machine.

Goodall shared, “This project has shown the large potential that Additive Manufacturing has for electrical machines, with lightweight, efficient structures that have never before been possible using any other manufacturing technique. It was a pleasure to work with the team at WEMPEC (an internationally renowned power electronics research and electric machines research group located at UW-Madison) to turn this idea into a reality.”

Download Metal AM magazine