Additive manufactured fuel pump tested for liquid methane NASA rocket in Mars project

May 5, 2016

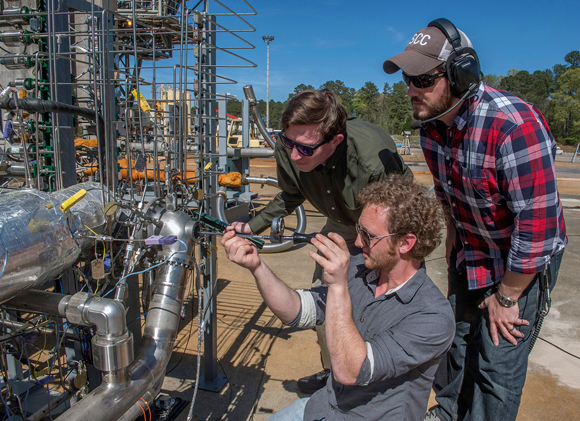

Engineers prepare the additive manufactured turbopump for a test at NASA’s Marshall Space Flight Center in Huntsville, Alabama. The turbopump was tested at full power, pumping 600 gallons of liquid methane per minute (Courtesy NASA)

NASA has reported that it recently tested a complex additive manufactured rocket engine turbopump with liquid methane, an ideal propellant for engines needed to power many types of spacecraft for NASA’s journey to Mars.

The turbopump consists of turbines that spin to drive the pump, which is used to supply fuel to the engine. During the full power test the turbines generated 600 horsepower and the fuel pump turned at over 36,000 revolutions per minute, delivering 600 gallons of semi-cryogenic liquid methane per minute, enough to fuel an engine producing over 22,500 pounds of thrust. Three other tests were completed at lower power levels.

“This is one of the most complex rocket parts NASA has ever tested with liquid methane, a propellant that would work well for fuelling Mars landers and other spacecraft,” stated Mary Beth Koelbl, the manager of the Propulsions Systems Department at NASA’s Marshall Space Flight Center in Huntsville, Alabama. “Additive Manufacturing, or 3D printing, made it possible to quickly design, build and test two turbopumps with identical designs that worked well with both liquid methane and liquid hydrogen propellant.”

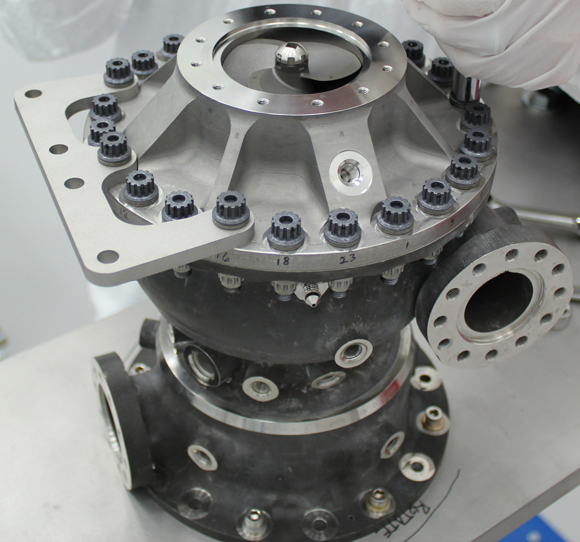

This rocket engine fuel pump has hundreds of partsincluding a turbine that spins at over 90,000 rpms. This turbopump was made with additive manufacturing and had 45% fewer parts than pumps made with traditional manufacturing (Courtesy NASA)

Hydrogen turbopump component testing and testing with a liquid oxygen/liquid hydrogen breadboard engine were completed in 2015. These tests along with manufacturing and testing of injectors and other rocket engine parts are paving the way for advancements in 3D printing of complex rocket engines and more efficient production of future spacecraft including methane-powered landers.

“Methane propulsion and Additive Manufacturing are key technologies for the future of exploration including NASA’s journey to Mars,” stated Graham Nelson, a Marshall propulsion engineer who helped with the testing. “We’re excited to complete testing that advances both these technologies at the same time and improves the capabilities of future missions.”

Liquid methane is cooled to -159°C whereas liquid hydrogen is cooled to -240°C. The higher temperature of liquid methane means it boils off more slowly and thus is easier to store for longer periods, a benefit for Mars missions. Also, technologies exist today to make it possible to manufacture methane rocket fuel from carbon dioxide, which is plentiful in the Mars atmosphere.

“By demonstrating the same turbopump can work with different fuels, we’ve shown that a common design would work for either engines fuelled by methane or hydrogen,” added Marty Calvert, the Marshall engineer who designed the turbopump. “Because liquid methane is much more dense than hydrogen, it requires the turbopump to spin at a different speed to deliver the same amount of mass flow to the engine.”

Testing ensures 3D printed parts operate successfully under conditions similar to those in landers, ascent vehicles and other space vehicles. All data on materials characterisation and performance are compiled in NASA’s Materials and Processes Technical Information System, called MAPTIS, which is available to approved users.

“Additive Manufacturing allowed us to build the turbopump with 45% fewer parts,” stated Nick Case, the Marshall propulsion engineer who led the testing. “This made it affordable to build two turbopumps, get them on the test stand quickly, and get results. Our next step will be to test the liquid methane turbopump with other 3-D printed engine components in a similar configuration to the liquid hydrogen tests completed last year.”