Additive Industries sells its first MetalFAB1 system in China

March 21, 2019

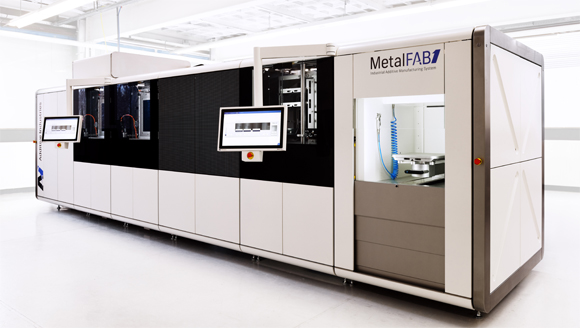

Additive Industries’ MetalFAB1 metal Additive Manufacturing machine (Courtesy Additive Industries)

Additive Industries, Eindhoven, the Netherlands, has received its first order for a MetalFAB1 Additive Manufacturing machine from China. This sale comes soon after the recent appointment of Sinsun-Tech Corporation Ltd as the company’s agent in the country.

The MetalFAB1 system will be installed at the Maritime Equipment Technology Institute of Jiangsu University of Science & Technology, and is expected to help the institute to accelerate production of heat exchangers for Liquified Natural Gas (LNG) applications.

Mike Goh, General Manager of Additive Industries Asia Pacific Pte. Ltd, stated, “We are proud to have sold the first system into China as this supports our expansion in the Asia-Pacific region. We will support the customer to build state-of-the-art heat exchangers through our regional Process & Application Development Centre in Singapore.”

“This is a fast and important step to enter the Chinese market with dedicated industrial Additive Manufacturing technology for series production. The high productivity of the system as well as the full automation will allow our customer to improve its business case,” added Wang Jun, General Manager of Sinsun-Tech.