3D Systems announces its next generation metal AM production platform

November 9, 2017

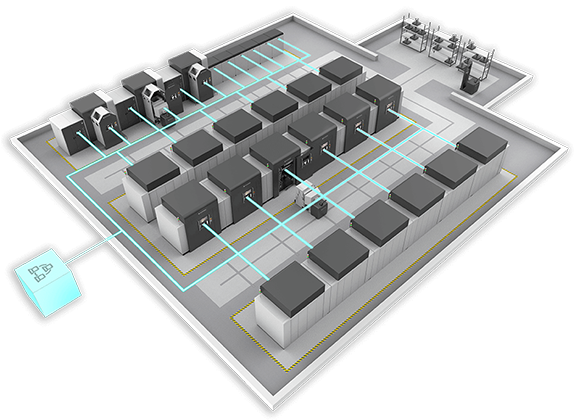

3D Systems’ ProX DMP 8500 modular AM factory solution

3D Systems, Denver, Colorado, USA, has announced its next-generation metal Additive Manufacturing production platform, designed to allow manufacturers to easily scale their AM production and integrate seamlessly into the factory floor.

Based on the company’s Direct Metal Printing (DMP) technology, 3D Systems claims that the DMP 8500 Factory Solution is the first truly scalable, automated and fully integrated metal Additive Manufacturing system. It features an efficient and fully integrated workflow, from powder in to part out, to produce repeatable, high-quality parts with a lower total cost of operation (TCO).

With a large diameter build size that is able to produce metal parts up to 500 mm x 500 mm x 500 mm, the system is engineered to open up new applications in Additive Manufacturing for companies in aerospace, industrial and automotive industries.

3D Systems stated that the modular design of this metal AM solution reduces required capital equipment and ensures maximum utilisation as manufacturers scale production. The DMP 8500 Factory Solution is comprised of function-specific modules designed to maximise efficiency by optimising the utilisation of each module, including:

- Removable Print Modules (RPMs):These sealed modules for powder and part transport between printer, powder, and transport modules enable a continuous production workflow and maximises powder quality throughout the process.

- Printer Modulesare designed to withstand the rigors of 24/7 production cycles enabling maximum printer uptime and output.

- Powder Management Modules (PMMs) efficiently de-powder parts on build platforms, automatically recycle unused powder materials, and prepare the RPM for the next build.

- Transport Modulesenable efficient movement of the RPMs between printer and powder modules – reducing production time.

“The industry is at a point where companies are looking to scale up their metal 3D printing production, bridge the chasm, and move onto the factory floor,” said Vyomesh Joshi, President and CEO, 3D Systems.

“The DMP 8500 Factory Solution was developed by experts with deep knowledge and experience in factory solutions and takes metal printing technology to a new level of economic efficiency for our customers.”

The DMP 8500 Factory Solution will integrate 3D Systems’ innovative 3DXpert™ software. This all-in-one software efficiently prepares and optimises parts for streamlined direct metal production of functional parts. The new platform is planned for availability in Q4 2018.

Proven LaserForm® Materials Portfolio Expanded

Building upon thirty years of experience developing next generation materials, the company also expanded its portfolio of ready-to-build precision alloys, formulated to deliver consistent part properties, build after build.

LaserForm Maraging Steel (A), a metal that can be machined, welded and hardened, was added to the portfolio. The new material is ideal for injection molding and tooling applications.

The company also introduced an upgrade to customers with an existing parameter set license for specific LaserForm metal materials which helps them achieve faster build times. The new Extra High Productivity Parameters for LaserForm Ti Gr5 (A) and Ti Gr23 (A) enable users to achieve high-speed metal printing with proven DMP quality. A high level of consistent, repeatable part quality is maintained, while build time is reduced by more than 30 percent resulting in lower part cost.