Z3DLAB releases enhanced nano-structured titanium powders for metal AM

November 26, 2018

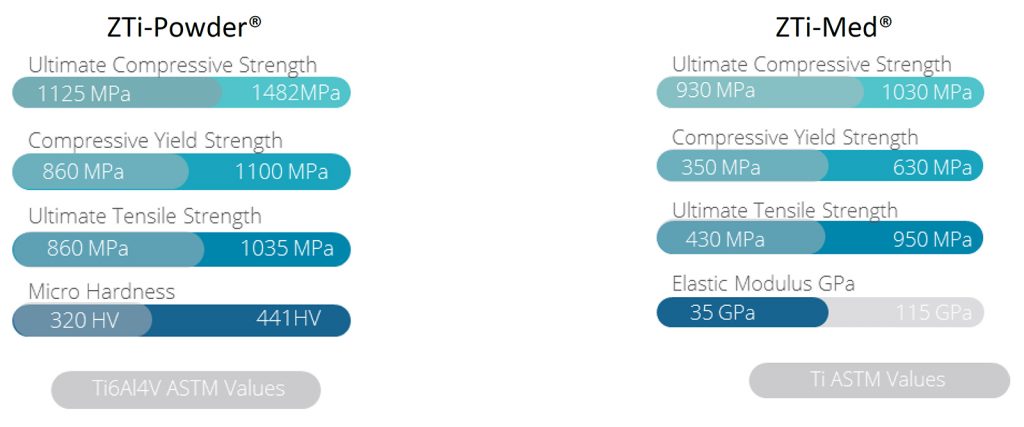

A comparison between the characteristics of ZTi-Powder and ZTi-Med with Ti-6Al-4V and Ti according to ASTM values (Courtesy Z3DLAB SAS)

Z3DLAB SAS, Montmagny, Val-d’Oise, France, has released its new nano-structured titanium powders, enriched by 1% nano-zirconium, for use in metal Additive Manufacturing. Founded in 2014, the company specialises in advanced non-structured materials for Additive Manufacturing, and believes that its new titanium powders provide better characteristics than standard titanium powders.

The company’s ZTi-Powder® range comprises nano-structured TA6V & zirconium powders with an ultimate compressive strength of 1482 MPa, a compressive yield strength of 1100 MPa, an ultimate tensile strength of 1035 MPa and micro hardness of 441 HV.

ZTI-Med®, a range of nano-structured titanium & zirconium powders, is designed to solve the stress shielding effect in medical implants, having an elastic modulus GPa of 35. ZTI-Med has an ultimate compressive strength of 1030 MPa, a compressive yield strength of 630 MPa and an ultimate tensile strength of 950 MPa.

According to Z3DLAB, the above material properties were achieved for parts produced in a standard titanium Powder Bed Fusion (PBF) Additive Manufacturing process, with none of the parts undergoing any design alternations. Madjid Djemaï, Z3DLAB CEO, stated, “We are pleased to make available the 1% enhanced nano-ceramic, with better results to what we obtained back in 2015 with 5%.”

“This will reduce resistance to change to its minimum and facilitate rapid adoption by both the medical and other industries,” he added. “The ZTi Family is here to replace the old titanium and bring new enhanced characteristics. A family of advanced material specifically designed for AM.”