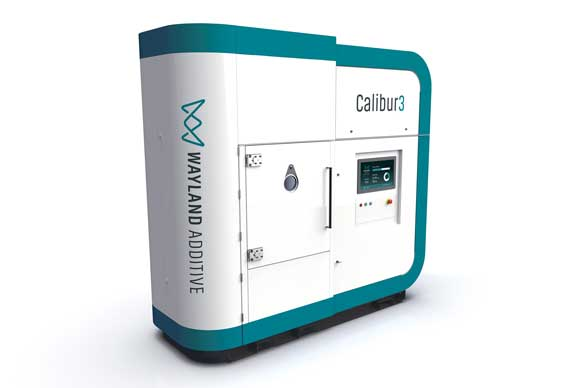

Wayland Additive and EWI finalise purchase of Calibur3 Additive Manufacturing machine

May 5, 2023

Following last year’s Memorandum of Understanding between Wayland Additive, Huddersfield, UK, and EWI Inc, headquartered in Columbus, Ohio, USA, the companies have announced that the purchase of the Calibur3 Electron Beam Powder Bed Fusion (PBF-EB) metal Additive Manufacturing machine has now been completed.

Mark Barfoot, Director of AM Programs at EWI stated, “At EWI, we identified the NeuBeam process and the Calibur3 system early on and recognised its potential for novel and exacting production applications of AM. Investing in this machine makes sense for EWI, but as any organisation serious about metal AM knows, securing the capital can take time. We are very pleased that the purchase of the Calibur3 has been finalised and look forward to taking delivery in the summer.”

EWI customers include aerospace and defence, automotive, aviation, energy, consumer electronics, medical devices, industrial products, and heavy equipment and, as a well-established, independent engineering consultancy with advanced manufacturing technology resources dedicated to production process development and improvement, EWI is said to be well-placed to maximise the potential of Calibur3. The machine’s proprietary NeuBeam process is said to provide users with greater flexibility for developing new applications with a broader range of advanced metal materials.

EWI’s Calibur3 is expected to ship in the coming weeks, in line with Wayland Additive’s goal of shortened lead times. The collaboration between Wayland and EWI has been ongoing and will continue once the machine is installed and running at EWI’s Buffalo Manufacturing Works facility in New York. Wayland will also deliver a sustainable new Mixed Reality (MR) service contract offering.

This upgraded service package will be delivered via RemoteSpark — a user-focused MR performance support tool that combines the physical and digital worlds by creating a hands-free, supportive environment and allows instant access to 2D and 3D holographic assets to support task completion, operational efficiency and training. In addition, it also allows immediate low-bandwidth, secure video and audio calls with any Wayland experts when necessary, circumventing the need for field engineers from Wayland to travel to across the Atlantic.

“We are delighted to be able to announce that the sale of Calibur3 to EWI has been finalised and completed,” commented Will Richardson, CEO at Wayland. “The commitment between Wayland and EWI has not faltered and I look forward to continued collaboration over the coming years. The delivery of Calibur3 to EWI will be rapid and I look forward to the many new opportunities that will arise. We are very excited to continue to support EWI and the Buffalo Manufacturing Works team going forward, especially via the Mixed Reality service agreement that has been put in place as part of the deal. At Wayland, we are always looking for ways to support our clients and give them the very best access to everything they need from us. RemoteSpark achieves exactly that along with peace of mind.”

Ron Aman, AM Senior Technology Leader at EWI added, “The team is very positive about adding Calibur3 to our existing metal AM processes at EWI and the new capability — and capacity — it will add. This system will enable us to extend the range of metal AM applications that we work on with our customers in the US and across the globe. We are also extremely pleased with the option to purchase the advanced MR service contract with Wayland. Their innovative approach to service engineering means that we will have full access to all of the digital assets we need, whenever we need them; as well as being able to call on any Wayland experts in a meaningful way, without having to arrange visits and travel between the UK and the US.”

Peter Hansford, Business Development Director at Wayland concluded, “It is extremely satisfying to see this purchase completed for both EWI and Wayland. The collaboration between the two companies has highlighted the synergies that exist as well as the potential for EWI that Calibur3 affords. EWI is a pioneer with metal AM for advanced manufacturing applications and with the experience and expertise of Ron Aman and his team, I know it is only a matter of time before new and exciting applications emerge.”

Download Metal AM magazine