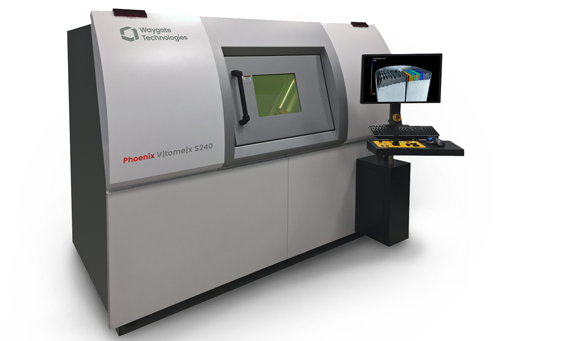

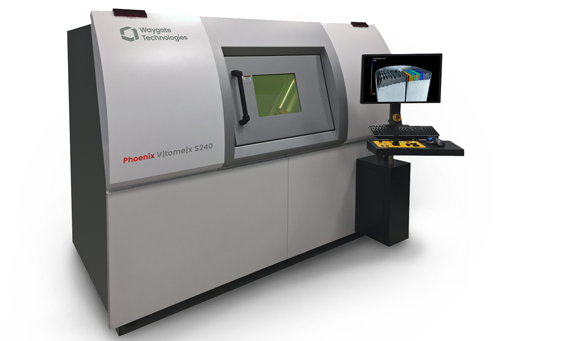

Waygate Technologies launches next generation Phoenix V|tome|x S240 CT system

September 26, 2020

Waygate Technologies, a global provider of non-destructive testing solutions and a division of Baker Hughes Digital Solutions, has launched the next generation of its industrial 2D radiography and 3D CT systems, the Phoenix V|tome|x S240.

The new V|tome|x S240 is said to cover a wide range of CT applications in research institutes and industrial quality labs, including internal defect analysis, 3D quantitative porosity analysis, materials structure analysis, assembly control, and coordinate measurement tasks such as CAD data nom/act comparison.

Reported to maintain its industry-proven, optional combination of both a nanofocus and microfocus X-ray tube, the new system is equipped with the Dynamic 41|200p+ detector technology that allows for higher resolution and image quality at much faster scan times. This proprietary device is well established with the premium system V|tome|x M. It doubles CT throughput at the same quality level as conventional DXR detectors by combining increased detector sensitivity and a larger imaging area, with faster frame rates and adaptive imaging modes.

By concentrating more power on a smaller focal spot, the optional High-flux|target offered by Waygate Technologies doubles resolution or scan speed. Production throughput can thus be increased even further without compromising on accuracy and precision, the company states.

The Phoenix V|tome|x S240 is capable of helical (or spiral) scanning with the sample moving upwards in the X-ray beam, thereby enabling faster scans of longer parts, and eliminating the need to stitch several partial scan results together afterwards. This acquisition technique is claimed to generate significantly better results by eliminating artifacts on horizontal surfaces and in the stitching areas.

The system is equipped with an advanced, highly intuitive CT scanning software for fully automated data acquisition and volume processing. In production mode, the entire CT scanning and evaluation process chain can be initiated, with 3D failure analysis or 3D metrology tasks executed automatically.