Waygate Technologies expands CT range with the new Phoenix Speed|scan HD CT system

October 30, 2020

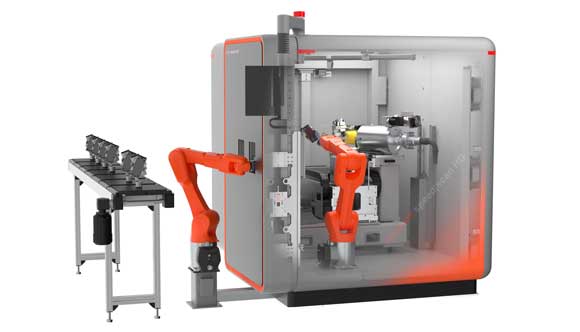

Waygate Technologies, Wunstorf, Germany, a provider of non-destructive testing solutions and a division of Baker Hughes Digital Solutions, is expanding its Computed Tomography (CT) product portfolio with the launch of its new Phoenix Speed|scan HD. The high-performance microCT system was developed for production environments with high throughput, and can be used in a variety of industries.

The new system is said to be particularly suitable for the increasing inspection requirements of the electronics and automotive industries, in medical technology and Additive Manufacturing. The company explains that its high degree of automation enables the inspection of large product quantities, twenty-four hours a day. Inspection efficiency is said to be further increased by artificial intelligence-based automated defect recognition (ADR).

To ensure a high-quality inspection, the Speed|scan HD provides detail detectability of up to 20 µm. The system can deliver error analyses, quantitative 3D porosity analyses, material structure analyses, and assembly checks or nominal/actual comparisons based on CAD data.

Dr Oliver Brunke, Application and Engineering Leader for industrial CT systems at Waygate Technologies, stated, “We have been the technology leader in high-speed CT inspection for many years, especially in automotive and aerospace applications. With higher-resolution images at the same high-speed throughput, Phoenix Speed|scan HD now expands the range of applications and sets new standards in multiple industries.”

The system has been designed for integrated use as part of the production line and includes a dual manipulator and double X-ray safety gate. It can also be used for metrology (the precision measurement of the geometry and dimensions of a part or product), making it a valuable asset for the development and design process.

“Thanks to our long-standing relationships with users in all kinds of industries and their feedback, the system offers a wide range of customisation options. With its high degree of automation, our new system allows a noticeable increase in production efficiency,” added Brunke.