Wall Colmonoy expands metal powder capabilities at European HQ’s R&D lab

June 18, 2020

Wall Colmonoy Limited has recently invested £500,000 in the research & development laboratory at its European Headquarters, in Pontardawe, UK, as part of its plans to improve product development, technical support and advancement.

The company explains that it has developed its R&D lab into a fully comprehensive suite of analytical equipment for characterising powders; including laser diffraction, chemical analysis, dry powder and fluid rheometry, and optical and electron microscopy. With a recent move into materials for Additive Manufacturing, where powder properties such as particle shape and size are often more critical, there was a need to expand its analytical capabilities.

“We know that particle shape directly influences Additive Manufacturing performance and our customers expect a

high-quality product with the correct size distribution and a spherical morphology,” stated Tom Roblin, Process Engineering Manager, Wall Colmonoy Limited. “We have manual microscopy and electron microscopy, which allow us to qualitatively check the products we manufacture, but we also needed a technique that could provide quantitative data on a statistically representative sample.”

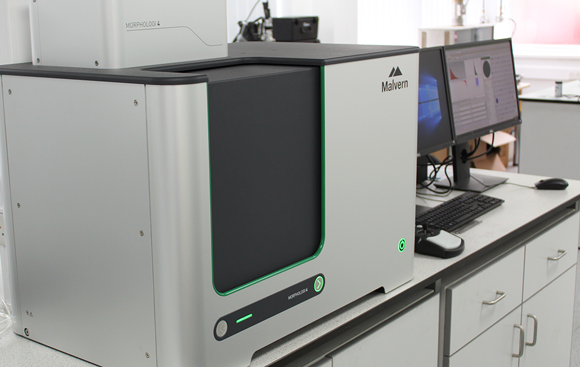

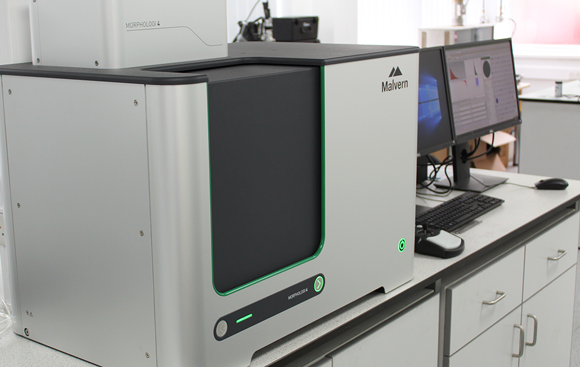

The company has now added a Malvern Panalytical Morphologi 4 to measure particle shape and size. The Morphologi 4 is said to provide an automated optical imaging platform capable of analysing a large number of particles and image analysis capabilities that automatically quantify the shape and size distribution of those particles.

“Morphologi 4 is used to quantitatively measure the particle shape of our atomised alloy powders,” Roblin added. “By investing in this measurement equipment, we can benchmark and improve our current processes and products. It will also aid in the development of a new range of Wall Colmonoy powders for Additive Layer Manufacturing. For us, it is a valuable tool that provides clear images, quantitative analysis and consistent results.”

The Morphologi 4 reports shape information using parameters such as elongation, circularity, convexity to quantify particle irregularity, and surface roughness. Said to be more efficient than manual microscopy and electron microscopy, automated imaging provides statistics on tens of thousands of particles. It has reportedly aided in the development of a new range of Colmonoy® (nickel-base) and Wallex® (cobalt-base) powders for Additive Manufacturing.

Wall Colmonoy states that its R&Dlaboratory is home to further metal powder analytical equipment including a full SEM / EDS suite, ICP Spectrometer and the Malvern Panalytical Morphologi 4.