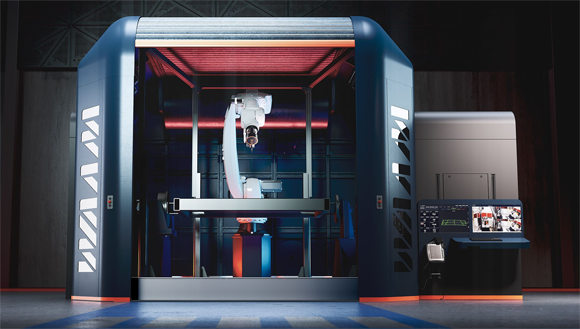

WAAM3D launches RoboWAAM large-format metal AM machine

June 9, 2022

WAAM3D, Milton Keynes, UK, has announced the launch of its RoboWAAM large-format metal Additive Manufacturing machine. The new machine, featuring sensing hardware and proprietary software, will increase the potential for multi-metre metallic part development in aerospace, defence, oil & gas and research communities.

WAAM3D, a company founded by a research team from the UK’s Cranfield University, has been pioneering research and development in the field of Wire Arc Additive Manufacturing, a wire-based Directed Energy Deposition (DED) process, since 2006.

RoboWAAM incorporates a number of innovative hardware features, which are reputed to be the first for large-format metal Additive Manufacturing. The company’s Real time ShapeTech™ is an interferometric sensor which reconstructs the 3D profile of the deposited structure, extracting the layer height value all around the component. It is intended to enable immediate confidence in the consistency of deposition and in the achievement of key geometrical targets, whilst Additive Manufacturing is in progress, removing the need for lengthy laser scans or touch-probe quality checks.

The machine includes double-point temperature measurement capability, leading the deposition to ensure consistent build conditions, and trailing the deposition for in-process parameters checks. Electronic wire positioning also offers increased process stability.

The new RoboWAAM machine has a fume management system (FMS™) with onboard fume confinement, filtration, and treatment. Global shielding for deposition of reactive materials, with fully automatic purging, atmosphere maintenance, and evacuation cycles is included, with the alternative of a new local shielding option for out-of-chamber deposition.

The RoboWAAM system is fed and controlled by WAAM3D’s own software suite, which consists of:

- WAAMPlanner® which turns a parts pre-form into executable RoboWAAM code. It includes planar and non-planar slicing, 2D and 3D sectioning, and layer grouping. It is capable of tool-path-planning with dedicated Additive Manufacturing approaches and multi-material and multi-process capability

- WAAMKeys can eliminate defects and keep the layer height under control. It carries out automatic parameter calculations, with advanced thermal compensation modules to achieve a target layer height, regardless of changes in geometrical features

- WAAMSim, is a simulation software that enables the visualisation of RoboWAAM’s deposition environment. It includes a virtual, gaming-inspired environment for collision detection and offline tool-path-plan validation

- WAAMCtrl® is an operating system for RoboWAAM. It incorporates an operator’s dashboard, the component’s digital twin, interactive data navigation, and historical database with complete build process record (parameter by parameter including all dependent variables, such as temperature and shape), integrated onto WAAM3D’s hardware and sensors

“With the launch of RoboWAAM, we have taken the production of large format 3D metal additive printing to the next level,” stated Filomeno Martina, CEO and co-founder. “RoboWAAM is capable of processing virtually any material available in the form of wire and it has a maximum build envelope of 2 x 2 x 2 m. This makes it the ideal 3D printing option for new as well as repaired metal components that require high structural integrity, cost effectively.”