Velo3D highlights advantages of F357 aluminium powder for Additive Manufacturing

June 17, 2021

When weight reduction is the primary goal, aluminium alloys are a frequent choice for aerospace and high-performance motorsports applications, explains Velo3D’s Zach Murphree, in this exclusive report for Metal AM magazine. Aluminium is much lighter than nickel alloy and has been particularly popular for Laser Beam Powder Bed Fusion (PBF-LB) Additive Manufacturing because it’s good for prototyping and easy to post-process.

There are, indeed, lightweight metal alloys with higher specific strengths (a better ratio of strength to density) than aluminium, such as the titanium grades. In the case of thermal management, there are certainly materials with better heat-transfer coefficients, such as copper alloys. For the lowest density or a higher galvanic potential, magnesium alloys are also a great choice. Despite this, aluminium alloys have persisted, because, when it comes to the trade-off between cost, performance, and manufacturability, they remain among one of the best materials to optimise all three, continues Murphree.

These same trade-offs drove much of the early development in aluminium when it came to metal Additive Manufacturing, especially PBF-LB. Aluminium alloys are generally grouped as either casting alloys or wrought alloys, and much of the original success in AM aluminium was with casting alloys. Wrought alloys can be desirable for demanding applications – particularly in aerospace where alloys such as 2024, 6061, or 7075 see a lot of use – but these higher-strength alloys suffer from poor weldability. Even 6061, which is considered to be a weldable aerospace-grade alloy, isn’t well-suited for PBF-LB. Since PBF-LB is, at its most basic level, a welding process, how can this be the case? It turns out that ‘weldability’ is not the primary criterion here, but, rather, ‘autogenous weldability.’

Autogenous weldability means that an alloy is weldable without a filler material, adds Murphree. This isn’t as much of a problem in a normal welding application, but the powder bed in an PBF-LB machine is a single material, meaning that there isn’t a great way to get a filler into the process. Because of this, alloys that aren’t autogenously weldable can present a problem – many of these cases have a tendency to crack in the build process.

As such, casting alloys took the lead in the development of aluminium for Additive Manufacturing. Some of the original success in AM aluminium came with AlSi12, an alloy that is 12% silicon. This is a fairly significant amount of Si for an aluminium alloy, but the Si serves to increase the flowability of the meltpool, and also to decrease the amount of contraction as the meltpool solidifies – in this regard, the more silicon, the better! But in the sense of mechanical properties, a high silicon content is not a good thing.

The next step was a logical one: reduce the proportion of silicon in the alloy from 12% to 10% and add magnesium to increase the strength. The result was AlSi10Mg, affectionately known by insiders as ‘alsitenmag.’

Even with the additional magnesium, however, AlSi10Mg wasn’t an ideal stopping point; parts built with it still didn’t meet many of the mechanical requirements of the final applications. This AM alloy tends to have low elongation, which is pretty significant: the higher the elongation, the tougher the material. Even with this deficiency, many people stopped here and settled for ‘alsitenmag’ as acceptable, even though it wasn’t what they were really looking for.

The safety factor

A large proportion of the applications that were good candidates for AM were originally castings in A356, one of the most widely-used cast-aluminium alloys, Murphree continues. It is lightweight and extremely corrosion resistant. To push the mechanical properties a bit further one can add more magnesium – this leads to A357, a stronger alloy that can be heat treated to better properties, but is a bit harder to cast. This could be an ideal candidate for PBF-LB, but there’s a catch: A357 also contains 0.04 to 0.07% beryllium—and beryllium is one of the most toxic metals to humans there is. Especially if it is inhaled, which can happen during powder handling and post-processing. Not an ideal fit for AM.

Fortunately, the beryllium can be eliminated from the alloy, with the result being F357 (‘F’ for ‘Free of beryllium’).

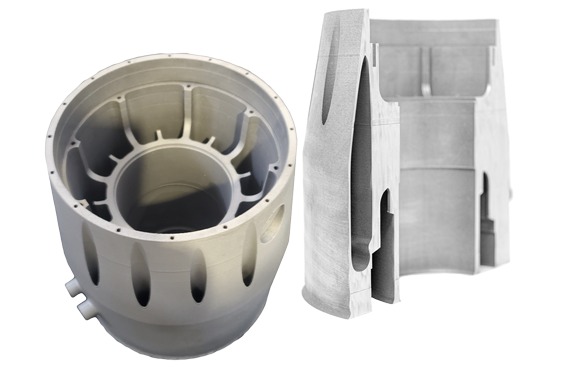

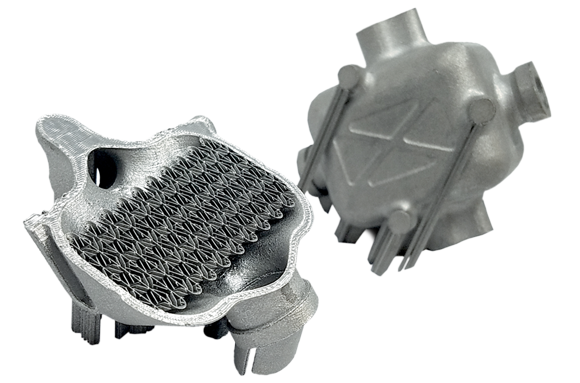

F357 is lightweight, offers great weldability, can be anodised, has high corrosion-resistance and is tolerant of a wide range of temperatures. It’s an excellent candidate for those AM parts with thin-walled, complex structures that you see in a number of aerospace and high-end motorsports applications.

While a number of leading AM equipment makers are exploring F357 now, if you have a need for this aluminium alloy, there are several things to consider as you decide on which PBF-LB AM machine to use to deliver your parts at the highest levels of quality.

Making aluminium F357 work for you

- Surface finish is important, especially at those increasingly low angles that AM machines can build at these days, sometimes completely support-free. Not to mention those complex interior geometries where post-processing a surface is limited, if not impossible. Many of the applications where you see F357 being used are in high-stress environments — and a superior surface finish right out of the AM machine provides better corrosion resistance and fatigue life.

- Hot tearing defects can occur with F357, because its reduced silicon content can lead to cracks as it cools. The most advanced AM machines have defined parameter sets and high-fidelity laser controls that are specifically tuned to address this potential problem.

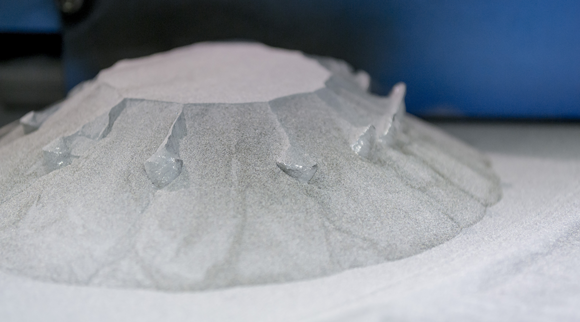

- Humidity can be another issue when you’re using aluminium. The powder is often ‘stickier’ and tends to clump, especially with ‘snowplow’ recoater systems. Aluminium powder is an excellent desiccant, and moisture will adsorb onto the surface of the particles immediately. When the humidity inside the build chamber creeps up, aluminium powder can be difficult to spread, and can often lead to build-killing powder-bed defects. A non-contact recoater completely avoids such problems. Also look for the tightest build chamber that can maintain extremely low oxygen and humidity levels, with active control of both at all times throughout the build.

The combination of F357 with the advanced metal AM capabilities now available provides significant advantages over AlSi10Mg and legacy metal AM systems, adds Murphree. It enables the elimination of engineering compromises that, in the past, could not be avoided, freeing the design engineer to achieve that desirable mix of geometric complexity and high performance at the lightest weights possible.

Contact:

Zach Murphree

Vice President Technical Partnerships VELO3D