Velo3D announces large-format Sapphire machine for metre-high parts

June 17, 2022

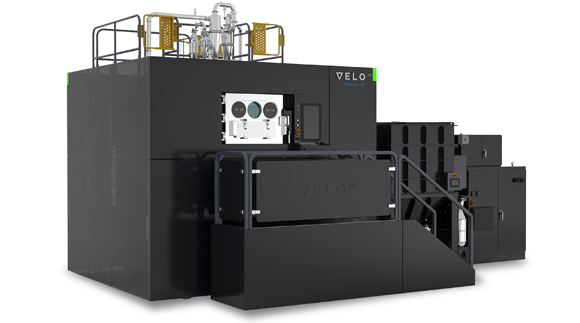

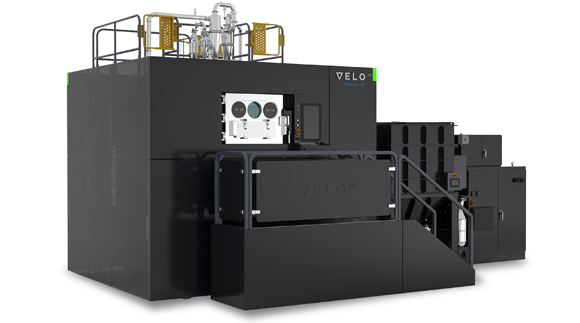

Velo3D, Campbell, California, USA, has launched its Sapphire XC 1MZ large-format metal Additive Manufacturing machine, capable of building components up to one metre in height. With a total build volume twice the size of the company’s Sapphire XC, and nine times the size of the original Sapphire, the Laser Beam Powder Bed Fusion (PBF-LB) machine is Velo3D’s largest volume AM machine to date.

The Sapphire XC 1MZ features eight 1 kW lasers and is reported to have an increased throughput of up to 400% over the original Sapphire machine. With a build volume of 600 x 1,000 mm, the new machine was designed based on feedback from customers in the aerospace, energy, and defence industries, with the first systems expected to be delivered to several aerospace companies in late Q3 2022.

“Without advanced metal Additive Manufacturing, it would be difficult to impossible to build many of the technologies that are shaping the future of our world,” stated Benny Buller, founder and CEO, Velo3D. “Our innovative customers have a clear understanding of how the technology can unlock new capabilities for their businesses and transform their product offerings. New systems, like the Sapphire XC and Sapphire XC 1MZ, support that transformation by significantly increasing throughput up to 400% and lowering costs by up to 75% compared to the original Sapphire.”

The Sapphire XC 1MZ will be compatible with all the materials currently offered by Velo3D, including Aluminum F357, Amperprint® 0233 Haynes® 282, GRCop-42, Hastelloy C22, Hastelloy X, Inconel® 625, Inconel® 718, Scalmalloy, and Titanium 6AI4V Grade 5.

More information on the Sapphire XC 1MZ is available here.