United Performance Metals announces new Additive Manufacturing centre

June 15, 2022

United Performance Metals (UPM), headquartered in Cincinnati, Ohio, USA, has recently unveiled its new Additive Manufacturing solutions centre in Hamilton, Ohio.

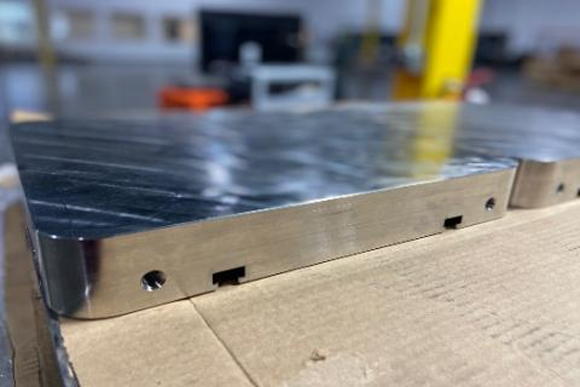

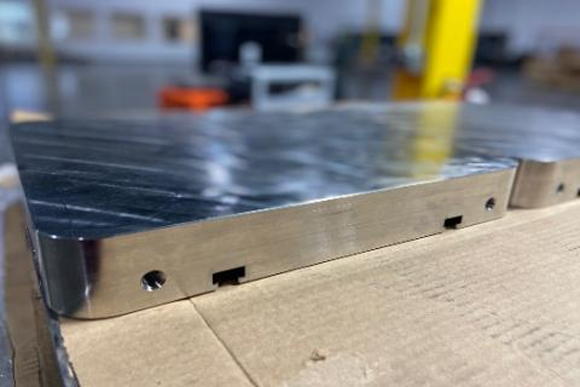

The new Additive Manufacturing centre provides stainless steel, nickel and titanium build plates which are said to be customised to any size or machine. UPM provides end-to-end supply chain solutions for the Additive Manufacturing market, from feedstock supply management to finished part manufacturing. The company also offers closed-loop refurbishment of existing build plates through additional milling and grinding, and wire EDM build plate removal.

“We are thrilled to launch our new innovative additive facility as it builds on our history of providing speciality solutions and services to the most innovative companies in the world,” stated JJ Johnson, General Manager of UPM’s new facility. “We have been working hard over the last two years to build this facility and the feedback from customers has been incredible. We are humbled and honoured with the customer response and are adding resources and capabilities to meet their evolving needs.”