TWI installs novel wire-feed head for Additive Manufacturing of tool dies

September 22, 2021

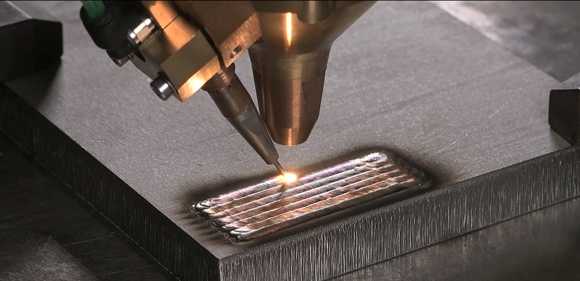

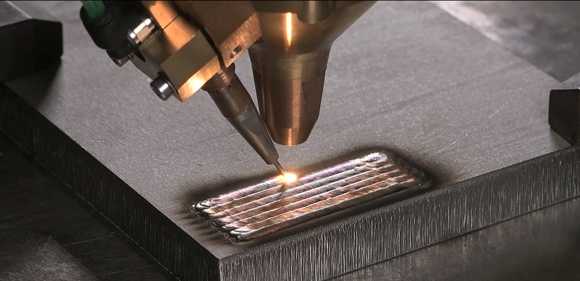

TWI, Cambridge, UK, has recently installed and integrated a novel wire-feed head for wire-based Directed Energy Deposition (DED), referred to by the company as wire laser metal deposition (w-LMD), in its KUKA robot cell. The head was designed and developed by Hybrid Manufacturing Technologies (HMT), Moira, Leicestershire, UK, as part of InnovateUK project FastWireAM.

Wire-based DED is an Additive Manufacturing technique which uses a laser beam to generate a molten pool of material onto a substrate. It then feeds wire feedstock – either coaxially or through a side-feed – into the melt pool to deposit a continuous bead of material. This deposited material is then built up layer by layer to produce the desired part.

The design of the head installed at TWI offers the simplicity of a side-feed set-up, whilst still allowing for stable effective-omnidirectional deposition of material. The system can also achieve a deposition rate of between 0.5 – 4 kg/hr, depending on the material and geometry requirements.

Current work is focussed on evaluating the stability and flexibility of the deposition process and developing a process window for a novel low-alloy tool steel feedstock developed by Epoch Wires. The company, alongside its FastWireAM partners, has already shown a use potential for the wire-based DED head by this feedstock as a coating for an automotive tool die provided by potential end-user DGWeld.

Watch TWI’s video demonstration here