Trumpf manufactures core component for CERN-coordinated project

November 18, 2022

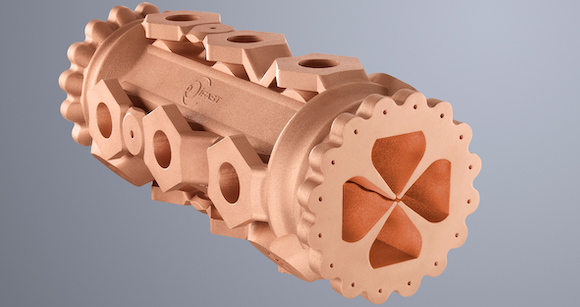

Trumpf, Ditzingen, Germany, has additively manufactured copper radio frequency quadrupoles (RFQs) – critical core components of future particle accelerators which provides energy to particle beams – for the first time as part of the EU-funded Innovation Fostering in Accelerator Science and Technology (I.FAST) project coordinated by CERN. This is said to mark the first time a copper RFQ has been manufactured in a single piece.

“This is proof that large copper components with a component height of nearly 400 millimetres can be manufactured additively with sufficient precision using our machines – or in other words: with 3D printing, we can manufacture even high-precision parts like this faster, cheaper and more energy-efficiently,” stated Michael Thielmann, Additive Manufacturing expert at Trumpf.

Maurizio Vretenar from CERN, project coordinator of I.FAST, added, “Over 30,000 accelerators are currently in use worldwide, the large majority of which is used for healthcare, and industry. Additive Manufacturing can help reduce the size and cost of all accelerator types, by improving and shortening their fabrication and enhancing their performance.”

Until now, suppliers manufactured the RFQs using conventional methods, which included many individual production steps such as milling and brazing were necessary. Additive Manufacturing eliminates many intermediate steps, especially when additively manufacturing complex features such as cooling channels. I.FAST’s team designed this copper RFQ specifically for the TRUMPF TruPrint 5000.

“With our green laser, we are also faster in the Additive Manufacturing of copper components than comparable systems with infrared technology,” Thielmann continued. “We need less energy to be as fast as an infrared laser – or we can work faster with the same energy.”

Trumpf intends to showcase the particle accelerator component at Formnext 2022.