toolcraft additively manufactures components for German armed forces

June 29, 2022

toolcraft AG, Georgensgmünd, Germany, reports it has been working with integrated technology group Rheinmetall AG, Düsseldorf, to additively manufacture components for Germany’s armed forces.

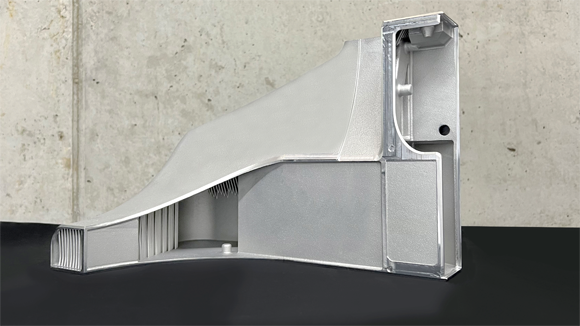

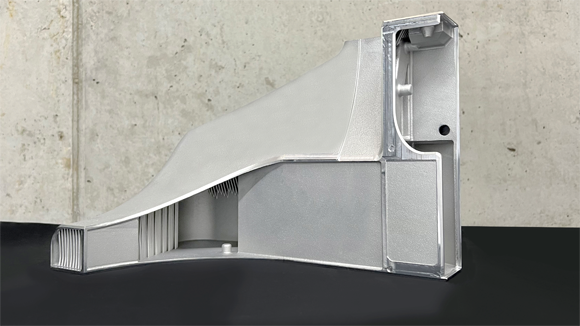

Rheinmetall commissioned toolcraft to manufacture components for a turret-independent secondary weapon system (TSWA), an unmanned weapon station mounted on the rear section of the German army’s Puma infantry fighting vehicle. The TSWA has a mount, launcher and an optical targeting system.

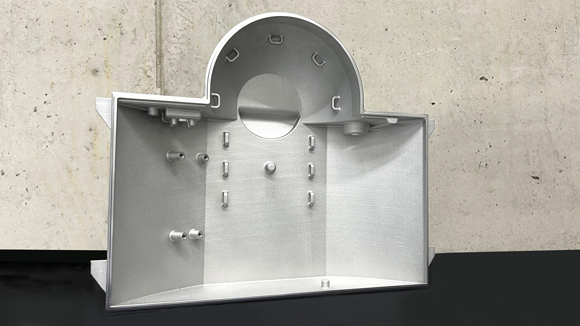

The additively manufactured components form part of the launcher, and include the structural support used to hold all the other parts, as well as the gate used to load and unload the launcher and prevent the ammunition from being removed without permission. The structural support also protects the electronics in a waterproof compartment.

The semi-finished products for the structural support and gate were additively manufactured, before undergoing heat treatment in a vacuum furnace to ensure they had the specified material characteristics. These individual components were then joined by laser welding with the addition of powder in a Laser Metal Deposition (LMD) machine. They were then post-processed to the required tolerances.

The way in which each component is segmented into sub-components which can then be additively manufactured was taken into account by Rheinmetall during the design phase. toolcraft used a range of quality assurance measures for the entire manufacturing process and the finished assembly, ensuring that the requirements of the DIN 2303 manufacturer certification for the production of defence-related products by means of Laser Beam Powder Bed Fusion (PBF-LB) and the LMD process were met at all times.

“The defence and security sector has strict component manufacturing requirements,” stated Christoph Hauck, Chief Technology Officer and Chief Sales Officer at toolcraft. “We are highly confident that our Additive Manufacturing process chain is capable of fulfilling all of these requirements.”

The TSWA was officially unveiled to the public during the celebrations held to mark the 50th anniversary of the Marder infantry fighting vehicle at the Munster Armoured Corps Training Centre on 21 October 2021. The weapon system is expected to become available for adaptation to the Puma following completion of the verification process in 2023.