Study showcases efficient and fully automatic finishing process for internal passages in AM parts

March 28, 2020

The mechanical and chemical engineering departments of the Politecnico Milano, Italy, together with Rösler Italiana S.r.l., part of Germany’s Rösler Oberflächentechnik GmbH, have conducted a study focused on automated post-processing, including the removal of residual powder and surface smoothing of complex internal channels, in AM parts.

The study looked at surface treatment using mass finishing, shot blasting and chemically supported mass finishing. The results of the study demonstrated that with all three methods, a significant improvement of the overall surface quality could be achieved.

The integration of internal functional features, such as precisely placed cooling channels within AM parts, is of great interest for tool and die making, hydraulic components and the aerospace industry. In the tool and die making industry especially, the integration of cooling channels offers significant technical advantages, because temperature fluctuations during the cool-down phase increase the risk of work pieces getting warped.

Moreover, as AM makes it possible for the geometry of a cooling system to precisely follow the contours of a component, overall cool-down times can be decreased considerably. Finally, because workpiece faults like warping and heat checks can be prevented, a more effective cooling function for injection moulded components results in a higher overall component quality.

Laser Powder Bed Fusion – Perfect shape, but high surface roughness

When additively manufacturing tooling components, Laser Powder Bed Fusion (L-PBF) is the primary production method and results in an extremely dense workpiece. The downsides of this process are that residual powder must be removed from the cooling channels and a high surface roughness of the components, having Ra values between 10 and 20 µm.

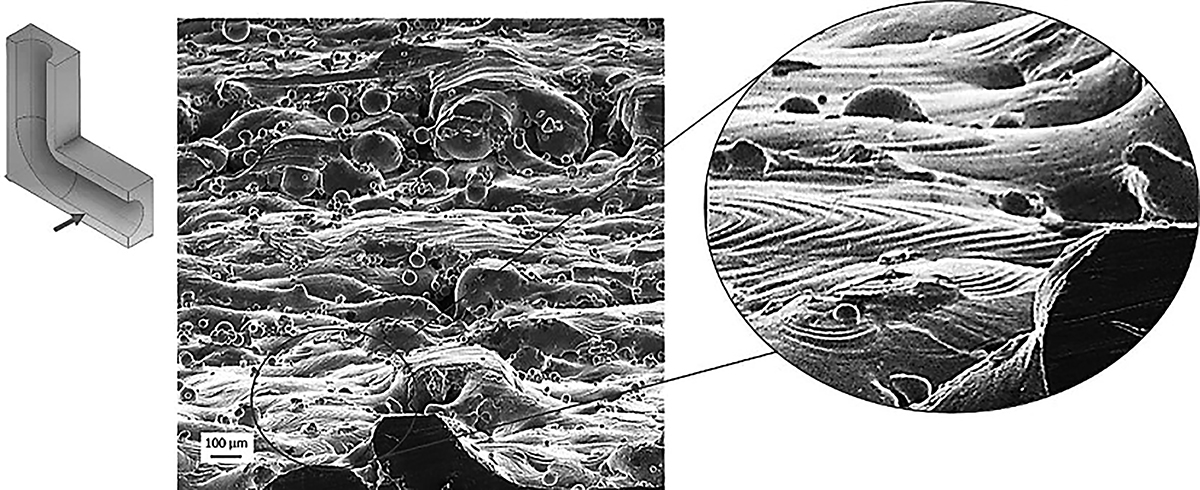

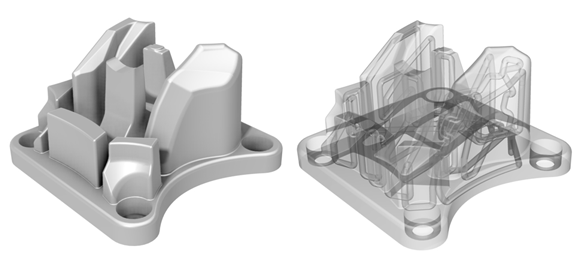

The surface, including internal passages, contains residual powder from the AM process and shows a high initial roughness (Courtesy Rösler)

A high surface roughness negatively impacts the functionality of the workpieces, resulting in reduced flow rates due to high friction, turbulences and pressure loss in the system. Any powder deposits and loose particles left in the channels can also damage other equipment. Since the internal surface areas of complex components with integrated cavities cannot be treated with conventional finishing technologies, new, innovative post processing methods are required. The choice of the most suitable surface finishing system is therefore critical for the service life of a component and the overall efficiency of a system.

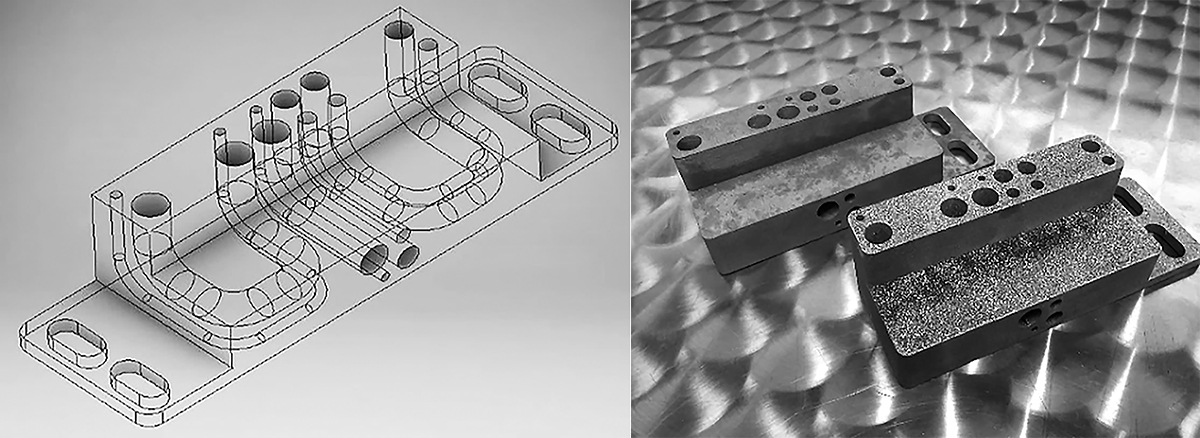

The study involved the treatment of parts with different shapes and internal passages with different diameters (3, 5, 7.5 and 10 mm) with mass finishing, shot blasting and chemically supported mass finishing. All three surface treatment systems were said to have produced surprisingly similar results. Conventional mass finishing and shot blasting consistently removed the roughness peaks and produced similar surface roughness profiles.

The trials were conducted with different geometries containing inner passages with diameters of 3, 5, 7.5 and 10 mm (Courtesy Rösler)

In the mass finishing method, the workpieces are immersed in a circular work bowl filled with special processing media. Vibrating of the work bowl causes the media and workpieces to move around in a spiral movement, and the constant friction of the media against the workpieces produces a grinding/smoothing effect, resulting in the desired surface quality.

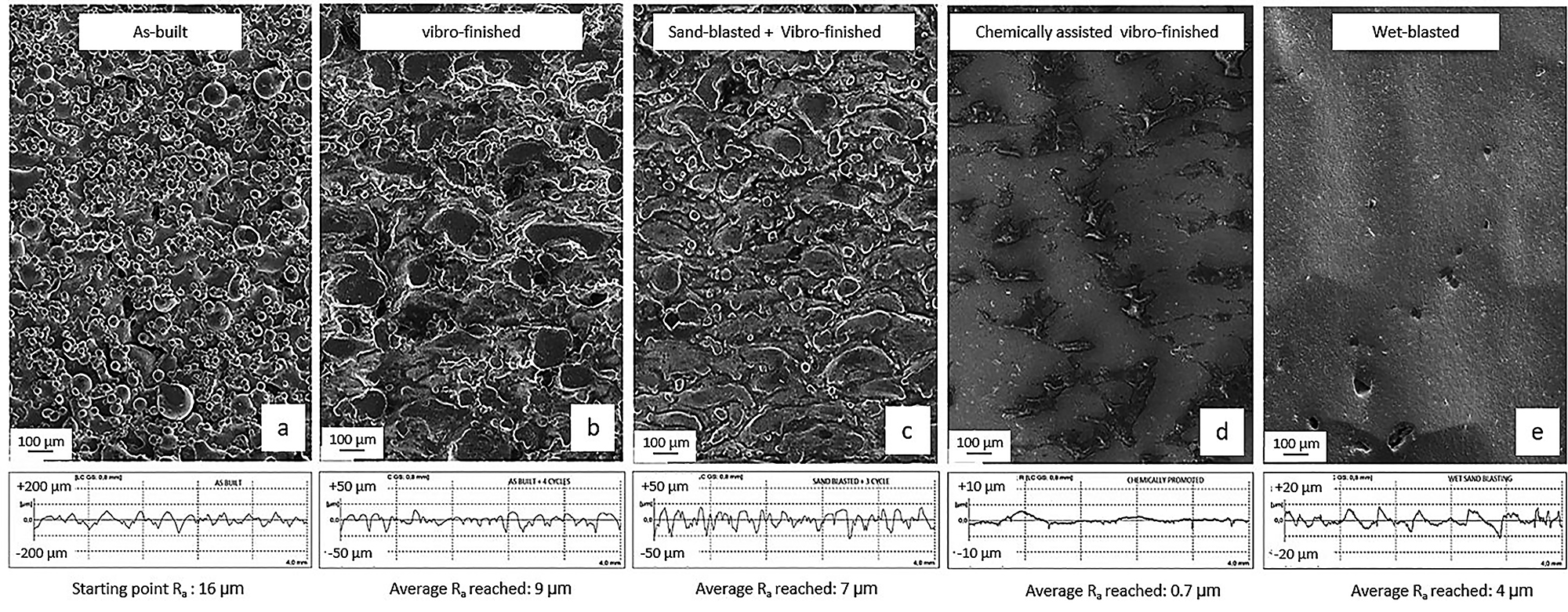

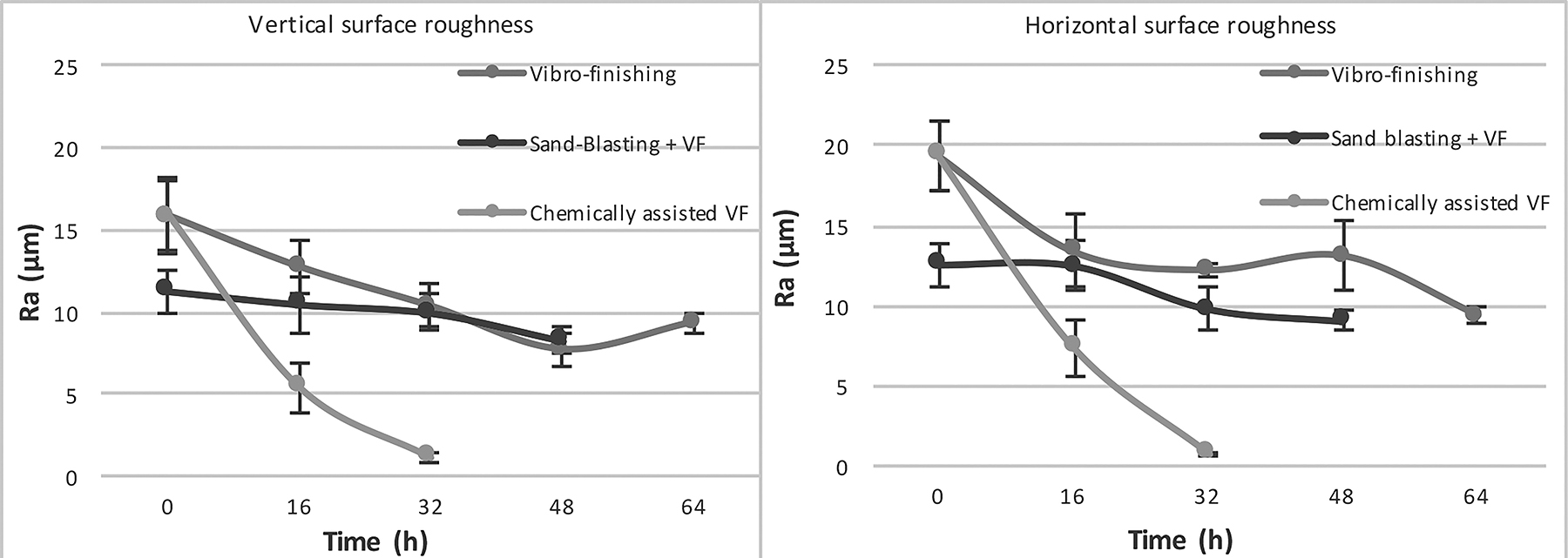

With Ra values of 0.7 µm the chemically supported mass finishing method produced not only the lowest surface roughness values, but it also required the shortest cycle time. The results also showed that the final roughness values were more or less identical in the vertical and horizontal internal passages.

Considering the surface structure of the internal passages and the initial high surface roughness of the 3D components, the trials clearly showed that the chemically supported mass finishing method produced the best finishing results (Courtesy Rösler)

The study proved that mass finishing can create the required smoothing effect on the internal surface channel areas without affecting the channel geometry. The treated surface areas were free of powder ‘splatters’ and loose powder remnants. All three treatment methods improved the surface roughness readings on the internal channel areas. However, the best results were achieved with chemically supported mass finishing: these work pieces had the smoothest surface, as shown by their comparatively lower surface roughness readings, and displayed the typical chemically accelerated finish.

With all three processing methods the achieved surface roughness values in vertical as well as horizontal internal passages were nearly identical (Courtesy Rösler)

Fully automatic processing in one machine

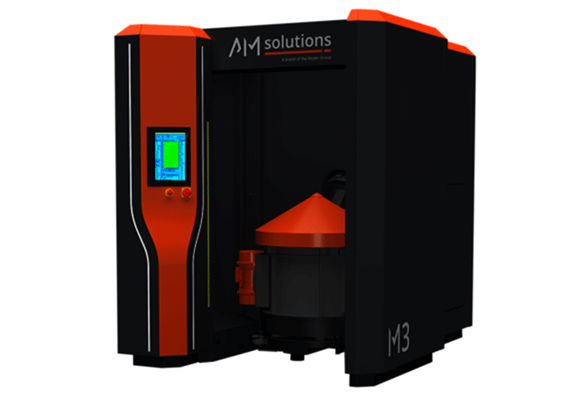

The above tests were conducted on an M3 machine from AM Solutions, a Rösler Group brand that specialises in the post-processing of additively manufactured components and offers a range of suitable equipment solutions, including the complete spectrum of post-processing functions like unpacking, removal of support structures, removal of residual powder, surface cleaning and smoothing, edge radiusing, high-gloss polishing and surface preparation for subsequent coating of AM components.

Further development of the M3 system is expected not only to allow the effective and targeted treatment of internal passages in the future, but to develop it into a fully automated system for consistent finishing of additively manufactured components without any manual work requirements. Loading and unloading of workpieces will also be automated.

The precise dosing of grinding media and compounds, dosing system and equipment ‘Start’ function will also be fully automated. Depending on surface finish requirements, several grinding and polishing processes can be run in sequence. After the automatic discharge of the media from the work bowl, the treated work pieces are removed from the clamping fixture. If required, a separate cleaning and drying stage can be added, also fully automated. Workpiece handling, including the transfer to subsequent manufacturing stages, will also be automated.

The system controls will reportedly allow the storage and call-up of multiple, workpiece-specific processing programs. The process parameters for the various work pieces can be selected by pushing a button or with a workpiece recognition system.

To date, internal workpiece passages that are difficult to reach could not be post-processed at all, or only with a high degree of manual labour. The automated post processing of AM components allows this work to be carried out within short cycle times at a fraction of the cost and, above all, with consistent finishing results.