Study looks to Ti-553 to improve osseintegration in metal AM implants

May 1, 2020

Recent research from Mohawk College and McMaster University, Hamilton, Ontario, Canada, has been published which shows how new combinations of materials and manufacturing techniques can improve the chance of osseointegration – bone in-growth – in metal additively manufactured bone implants.

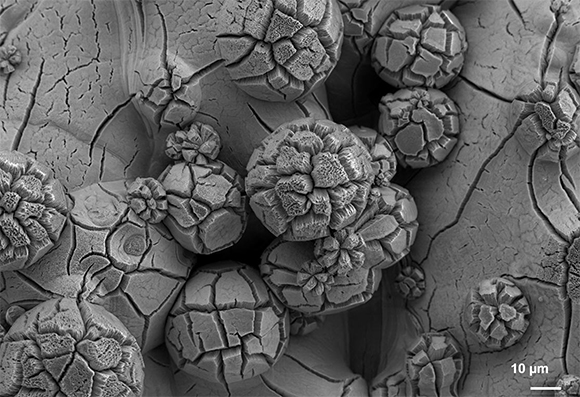

Most additively manufactured implants are produced using Ti64. Simon Coulson, General Manager of the Additive Manufacturing Innovation Centre (AMIC) at Mohawk College, partnered with Professor Kathryn Grandfield and her research team at McMaster University to evaluate the suitability of Ti-553 for use in these implants; in particular, whether its topography could improve osseointegration.

Because Ti-553 is not commercially available for Laser Powder Bed Fusion (L-PBF) Additive Manufacturing, the team partnered with Mohawk College to produce the metal samples needed for the research study. Coulson and his team validated the Additive Manufacturing process parameters needed to produce components from the novel material and manufactured the samples for the study.

“Our joint research with McMaster University has allowed us to make advances in the use of metal Additive Manufacturing for the medical sector,” Coulson told Metal Additive Manufacturing. “The development of new materials and surface modification techniques will hopefully improve patient outcomes during surgical implant procedures.”

The findings of the study, along with the parameters for Ti-553 for AM bone implants, were published in Nanotechnology. The study was authored by Chiara Micheletti, Bryan E J Lee, Joseph Deering, Dakota M Binkley, Simon Coulson, Asad Hussanain, Hatem Zurob and Kathryn Grandfield.