Study highlights energy usage in machined AM Ti-6Al-4V parts

January 10, 2023

Researchers at Italy’s University of Naples and the Italian Aerospace Research Center (CIRA) have undertaken work to identify the energy consumed in manufacturing Ti-6Al-4V parts via Electron Beam Powder Bed Fusion (PBF-EB) that have been post-processed by machining to achieve the desired surface finishing. Published in The International Journal of Advanced Manufacturing Technology, Ersilia Cozzolino, along with co-authors Stefania Franchitti, Rosario Borrelli, Carmine Pirozzi and Antonello Astarita, believe that the results of this study could find immediate practical application to improve the industrial sustainability of the production processes.

Although a number of studies have investigated the energy consumption of Additive Manufacturing processes, and many works are focused on the energy consumption of machining processes, the authors state that very few studies actually investigate the energy consumption of both AM and post-process machining combined. It is this gap of knowledge that the study aims to fill, as many AM parts require post-processing to meet the quality standard or to be assembled.

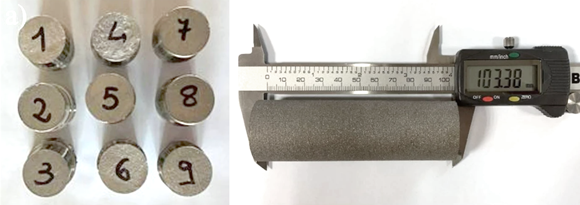

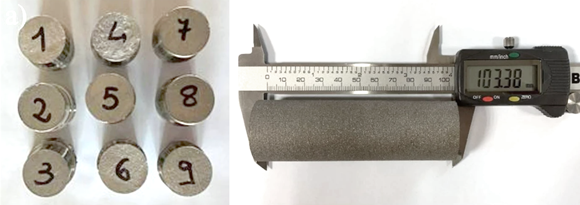

For the study, cylindrical specimens were manufactured using a GE Additive Arcam PBF-EB AM machine, under the processing conditions suggested by the manufacturer. The specimens were then turned under different processing conditions. The researchers noted the energy required in all the phases and carefully analysed the date to discover the processing conditions which allowed a more efficient use of resources.

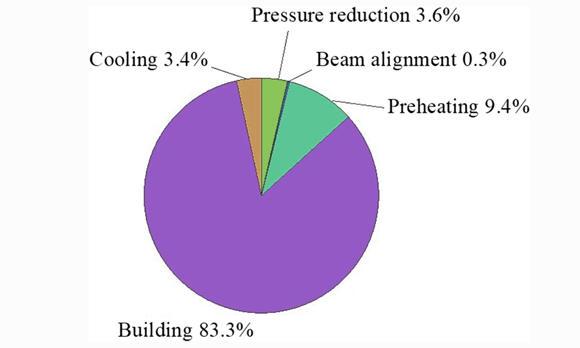

The results showed that the Additive Manufacturing build phase is by far the most energy demanding. The authors state that this stage should be optimised to reduce the build time as much as possible, even if a greater roughness is achieved. The analysis of the machining step suggested that both depth of cut and spindle speed must be kept as high as possible to reduce the energy consumption of this stage.

Although the process conditions during the turning stage were varied for all the samples, those in the PBF-EB process were fixed and the authors stated that further investigation may include the variation of the process parameters in the PBF-EB process by fixing those in post-process machining.

Read the full paper ‘Energy consumption assessment in manufacturing Ti6Al4V electron beam melted parts post-processed by machining’ here.