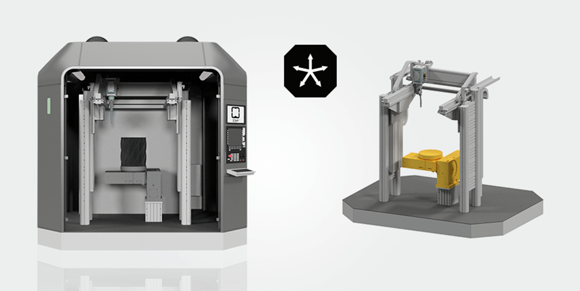

SLV Halle adds Gefertec’s arc405 metal Additive Manufacturing system

August 19, 2019

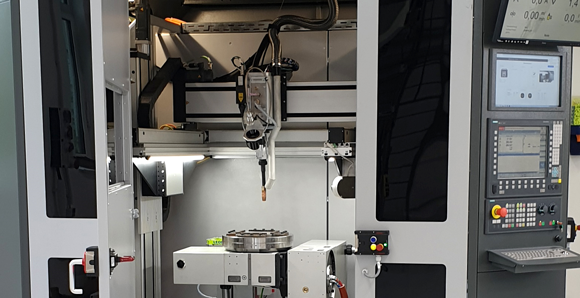

SLV Halle GmbH, a research institute, located in Halle (Saale), Germany, has invested in the arc405 system from Gefertec GmbH, Berlin, Germany. The metal Additive Manufacturing system uses Gefertec’s 3DMP® process and was installed at SLV Halle’s site in June this year. The company states that the machine produces metal components measuring up to 0.06 m3 with a maximum mass of 200 kg.

According to SLV Halle, by investing in the new machine, it aims to strengthen its position in Germany’s growth market for generative manufacturing and to promote interest in the further development of this technology. The company states that it received subsidies from the state of Saxony-Anhalt to purchase the arc405 system.

The machine will reportedly be used for additively manufacturing large-volume metal components for industries including steel/metal, rail/commercial vehicles, machine/plant, and pressure equipment construction. SLV Halle reports that the results of this work will be presented for the first time when it hosts its first Additive Manufacturing Symposium on November 12, 2019.

“We have no doubt that Additive Manufacturing processes can be implemented more frequently in today’s industrial production operations,” stated Prof Steffen Keitel, research institute director, SLV Halle. “The Gefertec arc405 enables us to drive the strategic expansion of our research infrastructure forward and make it easier for metalworking companies to integrate additive manufacturing processes.”