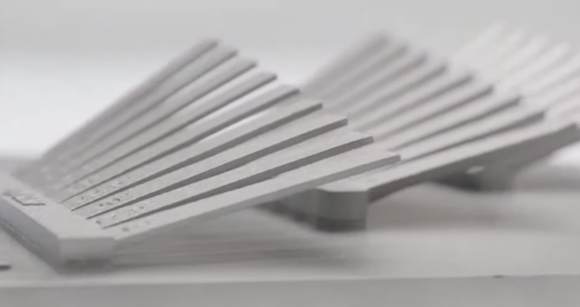

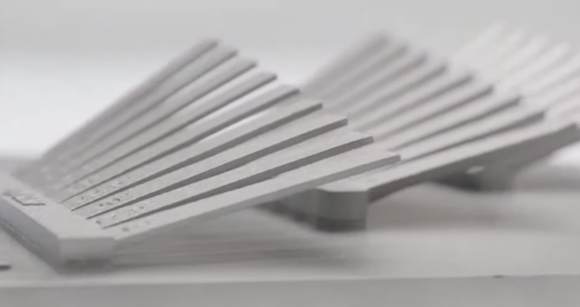

SLM Solutions reduces support structures with Free Float software

June 29, 2021

SLM Solutions Group AG, Lübeck, Germany, has launched Free Float, a software solution intended to reduce or remove support structures and enable new designs which reduce material usage. During the product’s virtual launch, CEO Sam O’Leary stated that a basic subscription to the software will be available at no cost.

Support structures have been an inherent part of the Additive Manufacturing process, explained SLM, with the design of the main component often limited due to necessary supports. These could make up a substantial section of the overall part volume, and yet needed to be removed during the post-processing phase, thereby increasing material usage and cost.

In 2017, SLM saw its first glimpse at what would become Free Float as a by-product of a research project. After some four years of further research and development, Free Float was officially born, establishing thermal management that decreases net build time whilst simultaneously enhancing part quality. This enhancement can be noted particularly in overhang areas – these can now ‘free float’ like the branches of a tree, added SLM.

In line with the company’s open architecture philosophy, Free Float was designed to be retrofittable on many previous systems, including the SLM®280 Production Series, the SLM 280 2.0, the SLM 500, the SLM 800, and the NXG Xll 600.