Siemens signs cooperation agreement with Göteborg Energi to test renewable fuels

December 7, 2019

Siemens AG, headquartered in Munich, Germany, and energy company, Göteborg Energi, Gothenburg, Sweden, have signed a cooperation agreement with the aim of testing state-of-the-art gas turbine technology that enables the operation of renewable fuels in the Rya combined heat and power (CHP) plant, currently powered by natural gas.

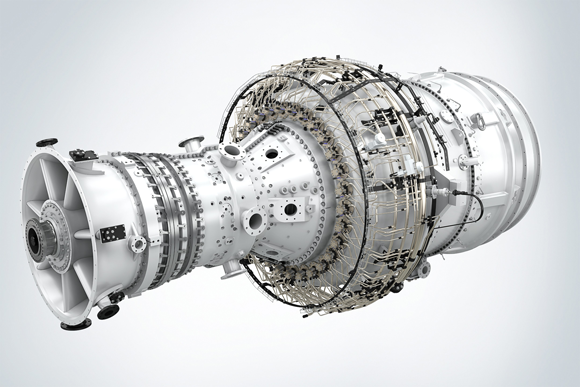

As part of the agreement, an SGT-800 test turbine has been installed at the Rya CHP plant for the validation of additively manufactured burners which would then allow for testing of different fossil-free fuels in the plant. The production of gas turbine burners using AM reportedly makes a decisive contribution to accelerating the research and development process for new technologies that contribute to a greener energy supply.

Siemens states that the Additive Manufacturing team within Siemens Gas & Power have recently initiated the development of a new accelerated validation process for new technologies and components, which is already said to be working in the Rya CHP plant. The special test engine is installed at the plant to support new developments. The Rya combined cycle power plant was delivered turnkey by Siemens in 2006 and includes three SGT-800 gas turbines.

According to Siemens, there is global demand for new climate-smart solutions and the company believes its technology and solutions are addressing this need. For example, converting a coal power plant into a modern gas-fired combined cycle power plant, such as the Rya CHP plant in Gothenburg, can reportedly reduce carbon dioxide emissions by about two-thirds. By co-burning natural gas with an increasing share of hydrogen or biofuel, emissions can then be further reduced gradually.

“The Rya CHP plant plays an important role in Gothenburg’s electricity supply,” stated Alf Engqvist, CEO of Göteborg Energi. “Working together with Siemens we want to explore the possibilities for the conversion of both electric power and heat production as pieces of the puzzle in our work for fossil-free energy independence.”

“In our collaboration with Göteborg Energi we see the possibility to verify the viability of several different renewable fuels, such as hydrogen, on a larger scale, first in Sweden and then in other parts of the world,” commented Thorbjoern Fors, CEO of Siemens Distributed Generation and Oil & Gas Services Business. “With this cooperation, Göteborg Energi and the Rya CHP plant are driving innovation toward new solutions and green power together with us.”

Fors continued, “Our goal is to run the SGT-600, -700 and -800 gas turbine combustors 100% fossil free, for example with hydrogen, in the near future. This is a unique cooperation between Siemens and a customer that can demonstrate the varied possibilities for sustainable and cost-effective fuels as our industry and societies look to reduce carbon emissions around the world.”