Second Gränges production facility, Finspång, achieves ASI certification

February 24, 2021

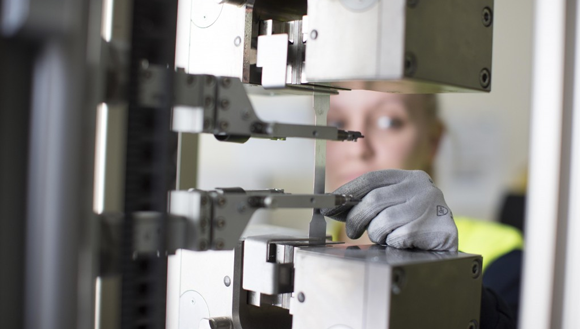

Global aluminium engineering company Gränges, headquartered in Stockholm, Sweden, has received a provisional certification against Aluminium Stewardship Initiative (ASI)’s Performance Standard at its production facility in Finspång, Sweden. The provisional caveat is due to an ASI interim policy regarding audits and travel, due to the current coronavirus (COVID-19) pandemic.

In late 2020, the company established Gränges Powder Metallurgy from its purchase of GETEK, GmbH and Dispal, a move it believes fits with the company strategy of working within markets of high-underlying growth and technology-driven consumers. Building on their aluminium materials offerings, this venture into Additive Manufacturing will allow the company to branch into new sectors, such as aerospace, industrial robotics, and motor racing.

“Achieving this ASI certification is an important milestone in our ambitious sustainability agenda and an important achievement in our work to constantly develop a broader and more sustainable customer offering,” stated Torbjörn Sternsjö, president of the European sector. “The certification verifies that our aluminium products are produced responsibly and sustainably and provides assurance to our customers and other business partners that we are committed to meeting their increased sustainability requirements and demand for sustainable aluminium. This is a first step towards being able to offer ASI-certified aluminium.”

ASI is a global, multi-stakeholder, non-profit standards setting and certification organisation which works to maximise the production and utilisation of sustainable aluminium. The ASI Performance Standard defines environmental, social & governance principles and criteria, addressing sustainability issues within the aluminium value chain. The independent, third-party audit of Gränges production facility in Finspång was carried out by DNV GL.

Gränges’ Shanghai site achieved ASI Performance Standard certification in 2019.

“We constantly develop and broaden our sustainable customer offering and work to create financial and operational value throughout the life-cycle of aluminium,” stated Johan Menckel, CEO. “The ASI is a very important industry initiative which enables us to promote and drive responsible and sustainable practices along the aluminium value chain. We now have certifications in place for two of our sites, and we will continue to achieve certification for our other sites.”