Sciaky to deliver industrial-scale metal Additive Manufacturing system to Airbus

December 14, 2016

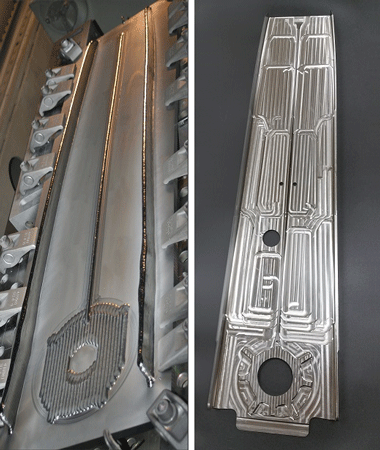

This photo highlights two different stages of an Airbus rear upper spar that was 3D printed in titanium with Sciaky’s EBAM process. The image on the left shows the part in an early preform stage. The image on the right shows the finished part.

Sciaky, Inc., a subsidiary of Phillips Service Industries, Inc. (PSI) based in Chicago, Illinois, USA, has announced that Airbus is to take delivery of one of its Electron Beam Additive Manufacturing (EBAM™) 110 Systems. The aircraft manufacturer will utilise Sciaky’s industrial-scale metal 3D printing system to produce large structural parts made of titanium.

Sciaky’s EBAM process combines computer-aided design, Additive Manufacturing processing principles, and an electron beam heat source. Starting with a 3D model from a CAD program, Sciaky’s fully-articulated, moving electron beam gun deposits metal via wire feedstock, layer by layer, until the part reaches near-net shape. From there, the near-net shape part requires heat treatment and post-production machining. In the end, there is minimal material waste.

“Sciaky is very proud to partner with a world-class innovator like Airbus,” stated Bob Phillips, Vice President of Marketing for Sciaky, Inc. “We all know that metal 3D printing technology is going to revolutionise manufacturing in the aerospace industry, and Sciaky is committed to being at the forefront of this movement.”

Sciaky’s lineup of EBAM systems can produce parts ranging from 8 inches (203 mm) to 19 feet (5.79 meters) in length. The machine can process a wide variety of metals and refractory alloys, such as titanium, tantalum, niobium, tungsten, Inconel, and stainless steels. Sciaky’s EBAM 110 has a work envelope of 70” (1778 mm) x 47” (1194 mm) x 63” (1600 mm).