Sciaky announces increased demand for its DED Additive Manufacturing solutions

July 7, 2020

Sciaky, Inc., Chicago, Illinois, USA, a subsidiary of Phillips Service Industries, Inc. (PSI), reports that it has seen an increase in demand for its wire-based Directed Energy Deposition (DED) Additive Manufacturing and welding solutions over the past two months.

During this period, Sciaky has reported a dozen new projects, ranging from high-level R&D projects to the production of prototype and production parts, mostly tied to the aerospace industry. Details of these projects are protected by nondisclosure agreements (NDAs), due to their confidential nature.

Of particular note, the company stated that many of these metal AM projects involve a wide variety of high-value materials, such as titanium, Inconel, niobium, copper-nickel and stainless steel. In addition, it noted that the quantity of material deposited during these DED jobs was particularly high for titanium, at 680 kg, and for copper-nickel at 498 kg.

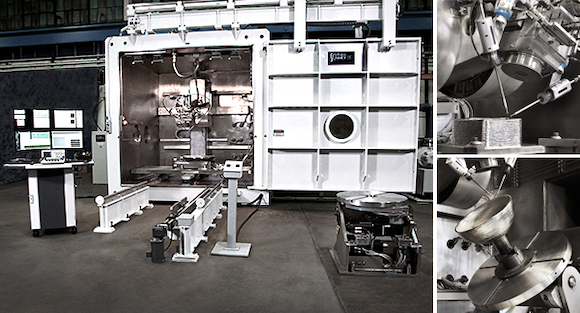

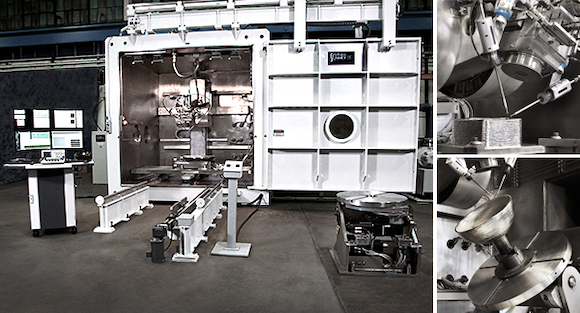

In Sciaky’s wire-based DED process, which it refers to as Electron Beam Additive Manufacturing (EBAM), wire feedstock is deposited and fused by exposure to an electron beam. Raw material is available in titanium, tantalum, tungsten, Inconel, niobium, nickel-copper/copper-nickel, aluminium, molybdenum, zircalloy, and stainless steel.

Sciaky’s machines can produce parts ranging from 203 mm to 5.79 m in length. Its DED process offers gross deposition rates of up to 11.34 kg of metal per hour. Sciaky’s machines also offer its Interlayer Real-time Imaging and Sensing System, IRISS®, a real-time adaptive control system said to be able to sense and digitally self-adjust metal deposition precisely and repeatably, helping to deliver consistent part geometry, mechanical properties, microstructure, and metal chemistry.

“Sciaky’s EBAM metal 3D printing technology provides the widest availability of cost-saving options for selecting high-value metal materials and producing large-scale parts,” stated Scott Phillips, the company’s president and CEO. “Every project is a new opportunity for Sciaky to prove the benefits of EBAM, which proves the industry is actively looking for new solutions to improve upon old processes.”