Sauber Technologies and Alfa Romeo F1 team extends partnership with Additive Industries

June 30, 2022

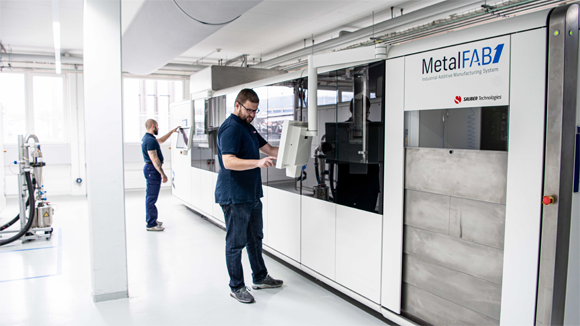

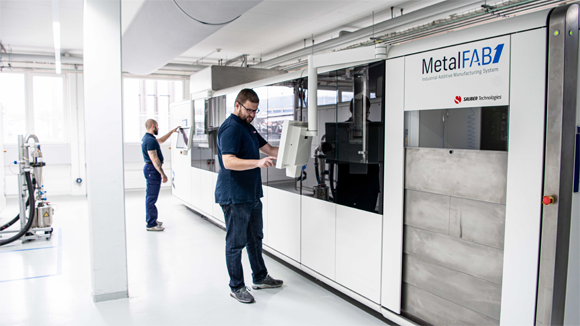

Sauber Technologies, part of the Sauber Group, and Alfa Romeo F1 Team ORLEN have extended their technology partnership with metal Additive Manufacturing machine maker Additive Industries, based in Eindhoven, the Netherlands, for a further three years. Sauber Technologies has been using Additive Industries’ MetalFAB Additive Manufacturing platform since 2017, and currently has four machines in-house.

With some fifty years of history in motorsport, Sauber is known for its racing activities, including sports cars and Formula 1. Sauber is currently competing in F1 with its Alfa Romeo F1 Team ORLEN, with drivers Valtteri Bottas and Zhou Guanyu. Sauber Technologies is fully focused on third-party business and provides a service for complex engineering applications, from the idea stage to the finished products.

The investment in the MetalFAB machines is said to have allowed Sauber to reduce cycle times in the manufacturing of parts for their own wind tunnel models, F1 cars as well as third-party business.

Christoph Hansen, COO of Sauber Technologies, stated, “Over the course of our successful partnership, Additive Industries have become an essential ingredient in the offering of Sauber Technologies. Ever since we introduced the MetalFAB systems to our processes, our in-house capabilities have increased in a significant way: Additive Industries continues to provide us with the best way to manufacture the most advanced parts for our motorsport operations, as well as our growing cohort of customers, reducing lead times, costs and waste while pushing forward the boundaries of technology.”

Mark Massey, Chief Commercial Officer (CCO) at Additive Industries added, “We are very proud to be constantly recognised by Sauber Technologies for our class-leading automated industrial metal Additive Manufacturing solutions. We encourage each other to push our boundaries and to innovate. We are committed to continuing our long-term partnership grow and evolve in the coming years.”