Sandvik opens its plant for AM titanium powders in Sandviken

October 28, 2019

Sandvik AB, headquartered in Stockholm, Sweden, has officially opened its new plant for the production of titanium powders for Additive Manufacturing in Sandviken, Sweden, with over 150 participants attending the opening event. The official ribbon cutting was performed by Lars Bergström, President of Sandvik Machining Solutions, and the Governor of Gävleborg, Per Bill, before an audience of plant employees as well as customers and end-users of the titanium powder.

Speaking at the opening, Peder Arvidsson, Process Owner Round Tools, and Matts Westin, Global Product Application Manager Milling, both from Sandvik Coromant, shared their experiences from the development of the lightweight cutting tool CoroMill® 390, and demonstrated how AM and titanium as a material both contributed to radical improvements in its performance.

Michele Antolotti, President, and Martina Riccio, Material and Special Process Manager, both from AM service provider BEAMIT, also shared case studies involving the AM of titanium for applications in the motorsports and racing sectors.

Following the opening ceremony, the full-day event programme included further talks from leading companies from sectors such as aerospace and medical, as well as many AM system producers. There were also discussions on new developments in metal powder and Additive Manufacturing, focusing on titanium powders and nickel-based superalloys.

According to Sandvik, the new titanium powder plant’s features include:

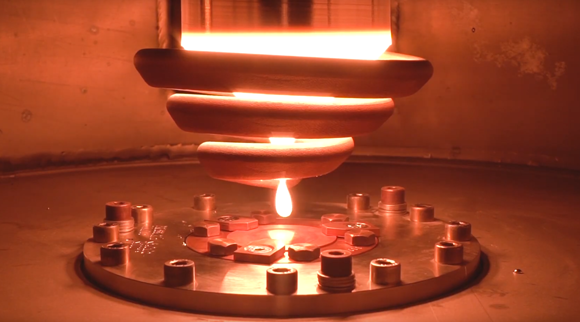

- A state-of-the-art atomising plant with electrode melting

- Electrode Inert Gas Atomisation technology (EIGA)

- The ability to atomise high-quality titanium powder with low oxygen and nitrogen levels

- A dedicated downstream sieving tower and large-scale blending and packing facility

- An additional sieving tower for nickel-based superalloys

- A highly automated workflow, aiding better reliability and consistency

- Full traceability, having the full supply chain in-house – from titanium sponge to finished powder

“Sandvik’s launch of titanium powders for Additive Manufacturing supports a growing trend towards the 3D printing of titanium parts,” stated Mikael Schuisky, Head of R&D and Operations in Sandvik’s Additive Manufacturing division. “The additive process results in far less material waste than traditional subtractive techniques, while also encouraging new levels of design freedom. This is opening up the use of titanium in other industries, such as automotive and tooling.”

Keith Murray, Head of Global Sales at the Additive Manufacturing division, commented, “With the addition of titanium powder, the Sandvik materials offering to Additive Manufacturing is complete. In addition, we can also tailor the powder to any printing process, thanks to our extensive in-house capabilities in Additive Manufacturing.”

“It was a great day with a lot of valuable customer interactions with some of the most important titanium powder users in the industry,” explained Kristian Egeberg, President of the Additive Manufacturing division. “Now we will gradually ramp-up the titanium powder production and continue to accelerate customer collaborations and development projects in parallel.”