Safina’s copper powder used in one of the world’s strongest magnets

October 11, 2021

Over its 100-year history, Safina, Vestec, Czech Republic, has established a strong position in the processing and manufacturing of precious and non-ferrous metal products such as thermocouple wires, PGM wires, plates and tubes, spray targets, laboratory supplies, chemicals, metal powders and more.

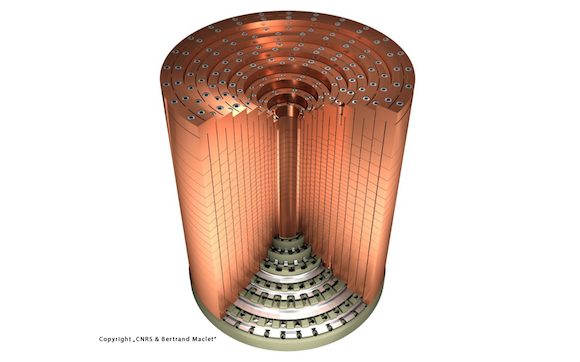

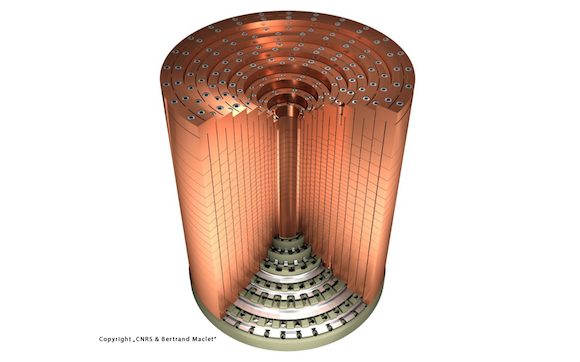

Now, with the company’s adoption and development of cold spray Additive Manufacturing, it is enabling its customers to produce high-power magnets. There are reported to be only four companies in the world able to operate with steady high magnetic fields, and one of them is a customer of Safina based in France. This customer is reported to have achieved a record induction of a magnetic field of more than 35 tesla, making it one of the strongest magnets in the world.

The internal electro-magnet was made of fourteen polyhelices, allowing a very high magnetic field in a series of parts which have to support thermal and mechanical constraints (up to 440 MPa and 170°C). With cold spray Additive Manufacturing it is possible to achieve higher properties than possible with forging (with forging, there is a limitation of yield strength and electrical conductivity).

The higher properties allow the installation to increase the available magnetic field for researchers. Such a high magnetic field is made possible by running up to 30,000 A per cm² in the helices, with AM enabling a cooling system to be integrated. It is also possible to tune several properties, such as yield strength and electrical conductivity, with different heat treatments.

Safina helped the company develop a bespoke copper powder based on very specific customer requirements. It was the ability to supply a metal powder from the alloy, in such a high quality, which was said to enable the customer achieve a high magnetic field induction.

The magnet has since been used by research institutions and universities for various physical experiments, such as understanding the processes of magnetic fields in space.