Safina offers range of metal powders for Additive Manufacturing

February 2, 2021

With beginnings in the mid-19th century, Czech company Safina has a long tradition in the complex processing and manufacture of products from precious and nonferrous metals such as thermocouple wires, PGM wires, plates and tubing, sputtering targets, labware, chemicals, powders and others.

For many years, the company produced silver powders – prepared by reduction from silver nitrate solution in a large range of particle sizes with dendritic shape. These powders are commonly used in the fields of sintered contacts, carbon brushes and EMI/RFI shielding. However, chemically-precipitated powders, such as these, are not suitable for technologies like Additive Manufacturing or cold spraying.

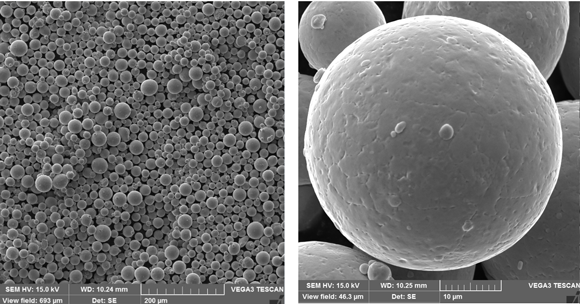

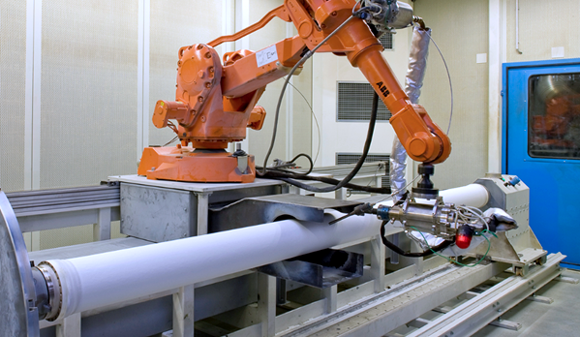

Safina initially invested in cold spray technology in 2012 for the production of rotary targets for the flat glass industry. Rotary sputtering targets produced from gas atomised powder by cold spraying ensure superior properties like low porosity, gas content, high purity – 4N, fine and homogeneous grain size. In line with this development, the company invested in a gas atomiser suitable for the production of silver powder for cold spray technology.

Safina soon became aware that its uniquely-developed processed powders have properties for cold spray and AM which the standard powders did not. With this in mind, it started the external production of gas atomised powder for partners, which is currently a keystone of the company’s portfolio.

Powders from Safina

Safina’s powder range extends to three main types: gas atomised; chemically precipitated; and its newly-developed coated powders, which are manufactured by hydrometallurgy.

Safina is focused on customised production according to the manufacturing method and demands, offering tailor-made solutions to its customers. Its powders are used in serial production for customers in the electronics industry and for high-end applications such as rocket combustion chambers for the aerospace industry.

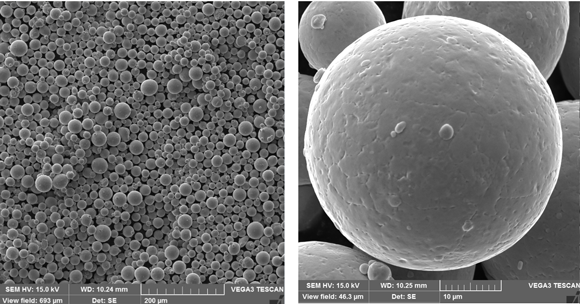

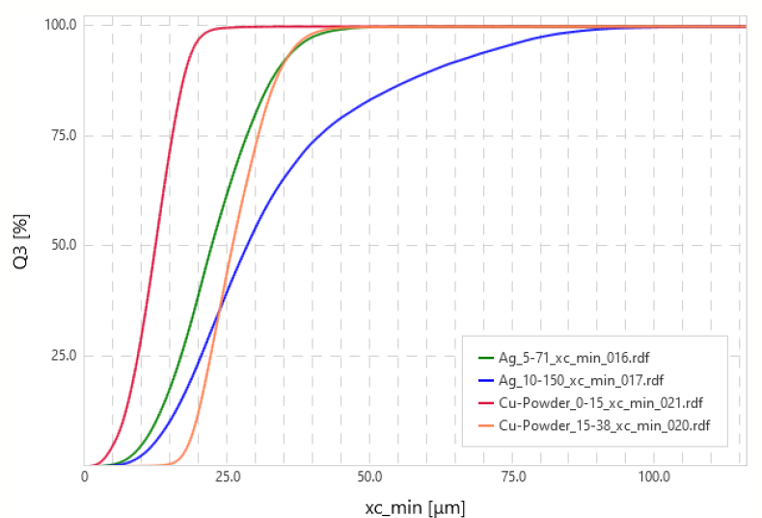

Inspection methods like sieving analysis, laser diffraction granulometry, dynamic image particle analysis, Scanning Electron Microscopy (SEM), chemical analysis by ICP-OES or EDX, gas content measurement, tap and apparent density/flowability measurements control the quality of the powders.

Safina’s background in the precious metals business has given the company extensive experience as a safe, reliable partner in the realm of recycling, striving towards very high purity and very low gas content of materials, which serves to improve the quality of products manufactured.