Saarland researchers report electrochemical method for high-precision metal AM part finishing

June 8, 2020

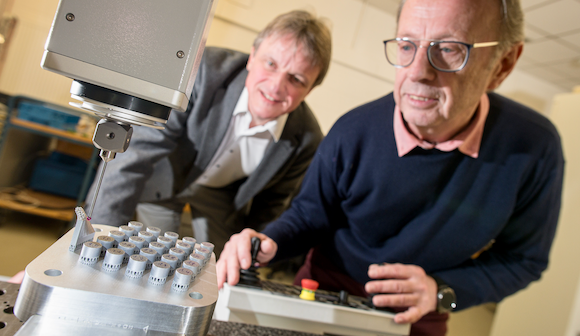

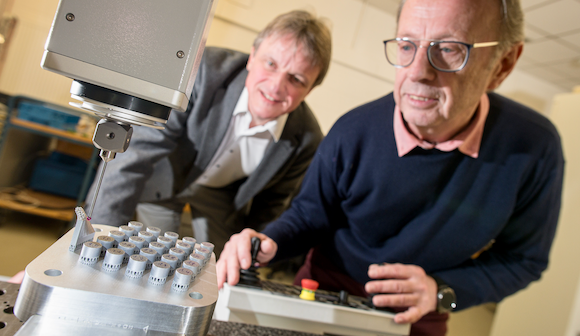

A research team at Saarland University, Saarbrücken, Germany, is studying a non-contact method for finishing high-precision metal additively manufactured parts, said to enable accuracy to within a thousandth of a millimetre. Using an electrochemical finishing process, the team has been able to achieve complex geometries in some of the hardest metals.

Metal Additive Manufacturing has a number of existing and potential applications in critical components, such as vehicle, aircraft and rocket engines, for innovative, lightweight parts. Such applications require parts be manufactured and finished to very tight tolerances, which can be difficult to achieve in as-built additively manufactured parts, making the finishing stage of production critical.

“The tolerances can be in the micrometre range,” explained Prof Dirk Bähre, leading a research team of fine machining specialists at Saarland University. “With our technologies for the post-processing of additively manufactured metal parts, we can produce precision functional surfaces for high-precision applications cost-effectively. Even large quantities can be produced economically.”

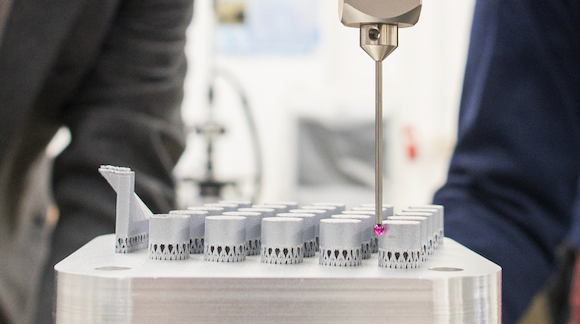

Electrochemical finishing, explains Bähre, “is a damage-free, non-contact manufacturing technology with which we can efficiently process complex components and high-strength materials.” AM parts, immersed in electrolyte solution, can be finished to the desired tolerances without introducing stress or mechanical changes into the material.

The electrochemical finishing process uses an electric current which flows between a template, cathode (finishing tool), and anode (the AM part). Flushed with the current-carrying electrolyte solution, imperfections are removed from the part as metal atoms on the material’s surface detach themselves as positive ions, enabling the part to be shaped to the desired precise geometry.

“By pulsing the current and vibrating the tool, we can achieve a particularly uniform removal with very smooth surfaces and high accuracies,” commented Bähre.

“In order to optimise post-processing, a deep understanding of the material and process is necessary,” he added. The researchers have investigated the use of electrochemical finishing on a number of additively manufactured materials, including aluminium, titanium and steel alloys, at every process step.

“For example, we need to understand exactly what happens to the metal in the previous 3D printing,” he continued. “Therefore, we investigate which structure is created. By researching processes and material behaviour, we can use them to further develop the electrochemical methods in order to obtain smooth surfaces or complex geometries with high precision.”

Bähre and his research team are said to be working with partners from science and industry on a number of projects, including the electrochemical finishing project, which are funded by the European Regional Development Fund.