Rotary surface grinders help to streamline build plate resurfacing

January 27, 2022

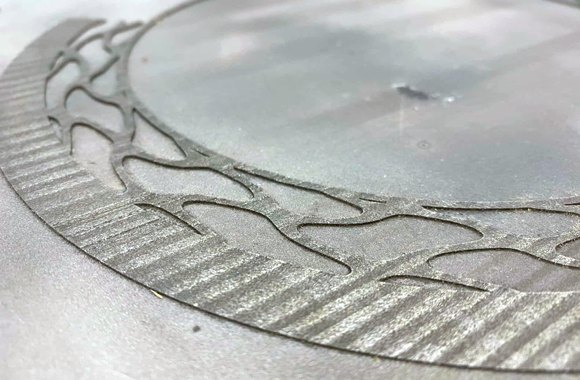

A number of metal Additive Manufacturing processes require the part to be cut from the build plate once finished. All residual metal left on the build plate between each build requires removal and the build plate needs to be completely level and correctly textured prior to additively manufacturing the next part. In series production, this can often result in a bottleneck, explains DCM Tech Inc, a producer of rotary grinders based in Winona, Minnesota, USA.

Since the metal part is ‘welded’ to the build plate, it is typically removed with electrical discharge machining (EDM) wire or a bandsaw. However, these approaches involve removing a thin layer of the build plate surface, gradually reducing its thickness until it is no longer usable. Most of the cuts are not entirely flat or level, either.

One alternative is to cut close to the part, but this leaves material that must be removed later. With EDM and bandsaws, the process can take hours and hard materials like Inconel tend to strain-harden, further increasing the difficulty. Some shops even address the issue with a CNC milling machine, but this can also take hours and limit the availability of the equipment for actual production. Exceptionally hard AM materials like Inconel and titanium further lengthen the required milling time.

A more efficient alternative, explains DCM, utilises advanced precision rotary surface grinders to remove unwanted residual material with a large rotary grinding wheel surface. This technology has long been used in metalworking and glass grinding to create perfectly flat, parallel surfaces. The equipment is ideally suited to the AM process and quickly and accurately removes any residual metal from the build plate surface, restoring it to precise dimensions.

The most advanced units even offer automation that allows minimally experienced operators to set them up and then attend to other tasks. This comprehensive approach is helping to exponentially speed build plate resurfacing, boost AM production, and improve quality.

“With advanced rotary surface grinders, our AM build plate resurfacing process is significantly more efficient, precise, and flexible. Incorporating the units in our process will help us handle high expected growth in the AM market,” stated Doug Hedges, CTO of Beehive3D, Inc, Deerfield Beach, Florida, USA, an AM provider to aerospace, defence, and turbine markets.

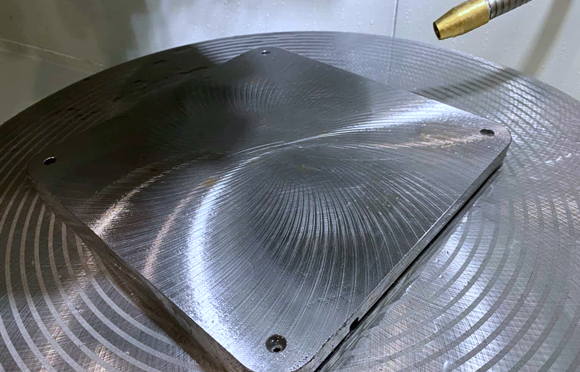

According to Hedges, it is critical in Beehive3D’s Laser Beam Powder Bed Fusion (PBF-LB) to resurface the build plate to precise process tolerances prior to re-use. “Not only do you have remnants of metal on the build plate, but also portions of the build plate can become bowed or distorted so it needs to be resurfaced after each use to keep it flat and parallel,” he added.

More advanced units, such as those from DCM Tech’s IG series, offer variable speed grinding with automation and controls that allow virtually any operator to successfully manage a unit. These units can control the initial contact between the abrasive wheel and the build plate, which, in the past, had to be controlled by the operator. Advanced sensor technology detects vibration and can automatically fine-tune the pressure of the spindle motor and how quickly it moves the wheel down onto the build plate. When the machine senses the abrasive wheel has contacted the build plate, it automatically begins the grind cycle.

One aspect that expedites production is the operator’s ability to accommodate grinding of extremely hard residual material like Inconel or titanium from build plates. This typically involves working with an expert vendor that can tailor the surface grinder’s abrasives to accommodate different types of metals and alloys, as well as the materials used for the build plate.

Beehive3D currently uses DCM Tech IG series rotary surface grinders at some of its locations and has expressed plans to add more in the future. Hedges has stated that Beehive3D has found value in working with a vendor that can tailor the rotary surface grinder to the company’s specific needs.

“Using the proper abrasives and feed rates can reduce finishing time and facilitate an efficient, repeatable process. Working with an expert in abrasive use like DCM Tech gives us the flexibility we need to efficiently remove a range of metal remnants such as aluminium, titanium, and Inconel from the build plates,” he stated.

Also important is the ability to alter the parameters through the grind cycle to handle both the additively manufactured metal/alloy and the material used for the build plate. The material characteristics of the build residue and the build plate are very different, so the rotary grinder must appropriately adjust to each on contact. Once the grinder cuts through the residual part material and reaches the actual plate, the grinding abrasive must work completely differently. The rotary grinders automatically make that transition.

“Unlike older style machines, the advanced rotary grinders do not need constant operator input or oversight. This allows the operator to multitask and minimises the risk of error,” concluded Hedges.