Rolf Lenk GmbH adds Gefertec GTarc system to its service offering

June 11, 2018

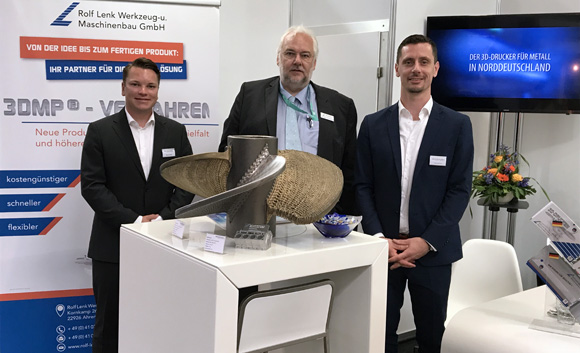

Rolf Lenk GmbH formally closed the deal to acquire a GTarc 3DMP system during Rapid.Tech 2018 (Courtesy Gefertec GmbH)

Rolf Lenk Werkzeug-und Maschinenbau GmbH, Ahrensburg, Germany, has added a GTarc Wire Arc Additive Manufacturing (WAAM) system from Berlin-based Gefertec GmbH to its metal Additive Manufacturing operation.

The company has been using metal AM for more than ten years, and stated that the GTarc machine will allow it to substantially expand its portfolio for customers from the medical engineering and automotive industry to machine and plant engineering, as well as in maritime construction.

Gefertec’s patented 3DMP® technology provides the basis for its GTarc machines. Using this electric arc-based technology, near-net-shape parts are formed by welding wire feedstock layer by layer. This is said to be faster and more cost-effective compared to powder-based methods.

The GTarc machine is available in four different models for the production of parts in sizes up to 3 m3. An accompanying 3DMP CAM software is also available; this calculates the data out of the CAD model to enable the CNC-control unit to position the welding head with high precision. The machine then produces the near-net-shape part fully automatically. The cost of GTarc machines is said to be comparable to that of a small CNC milling centre; significantly lower than many metal AM systems.

The contract between Gefertec and Rolf Lenk was reportedly closed during Rapid.Tech 2018 in Erfurt, Germany. Rolf Lenk will speak on the possibilities and applications of this technology at Gefertec’s 3DMP Forum, Berlin, June 21. Further companies, including Siemens, Airbus and FIT AG, will also demonstrate their work during the forum, while Gefertec is set to celebrate the opening of its new Application Center.