Researchers show heat treatment allows AM part to withstand extreme conditions

November 18, 2022

Researchers from Massachusetts Institute of Technology, Cambridge, USA; University of Illinois; and Oak Ridge National Laboratory, Tennessee, USA, have developed a heat treatment that transforms the microscopic structure of additively manufactured metals to make the materials stronger and more resilient in extreme thermal environments.

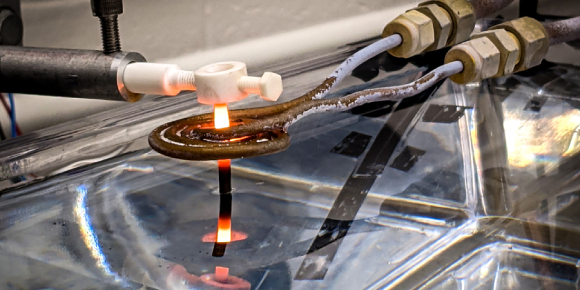

In the paper ‘Directional recrystallization of an additively manufactured Ni-base superalloy,’ published in Additive Manufacturing, researchers converted the fine as-built grain structure of Ni-base superalloy AM IN738LC to a course columnar one via directional recrystallisation The directional recrystallisation behaviours of AM IN738LC were characterised through a parameter study in which the peak temperature and draw rate were each independently varied.

Recrystallisation began when the peak temperature was higher than the γ′ solvus of 1183 °C. Varying the draw rate from 1 to 100 mm/hr while maintaining a fixed peak temperature of 1235°C and a thermal gradient of order 105°C/m ahead of the hot zone showed that a draw rate of 2.5 mm/hr maximised the grain size, giving a mean longitudinal grain size of 650 µm. Specimens processed under these conditions also inherited the〈100〉fibre texture of the as-manufactured material. Close inspection of a quenched specimen revealed Zener pinning of the longitudinal grain boundaries by MC carbides and a discrete primary recrystallization front whose position followed the γ′ solvus isotherm.

The present results demonstrate – reportedly for the first time – how directional recrystallisation of additively manufactured Ni-base superalloys can achieve large columnar grains, manipulate crystallographic texture to minimise thermal stresses expected in service, and functionally grade the grain structure to selectively enhance fatigue or creep performance.

This technique may make it possible to additively manufacture high-performance blades and vanes for gas turbines and jet engines, enabling new designs with improved fuel consumption and energy efficiency.

“In the near future, we envision gas turbine manufacturers will print their blades and vanes at large-scale Additive Manufacturing plants, then post-process them using our heat treatment,” stated Zachary Cordero, the Boeing Career Development Professor in Aeronautics and Astronautics at MIT and lead author of the paper. “3D printing will enable new cooling architectures that can improve the thermal efficiency of a turbine, so that it produces the same amount of power while burning less fuel and ultimately emits less carbon dioxide.”

The full paper is published here.