Researchers detect AM keyhole defects in real time

January 16, 2023

A team including researchers from the University of Virginia (UVA), Carnegie Mellon University, and the University of Wisconsin-Madison, have published a paper in Science addressing the issue of detecting the formation of keyhole pores, identified as one of the major defects that can occur in Laser Beam Powder Bed Fusion (PBF-LB) Additive Manufacturing.

The formation and size of the keyhole is a function of laser power and scanning velocity, as well as the materials’ capacity to absorb laser energy. If the keyhole walls are stable, it enhances the surrounding material’s laser absorption and improves laser manufacturing efficiency. If, however, the walls are wobbly or collapse, the material solidifies around the keyhole, trapping the air pocket inside the newly formed layer of material. This makes the material more brittle and more likely to crack under environmental stress.

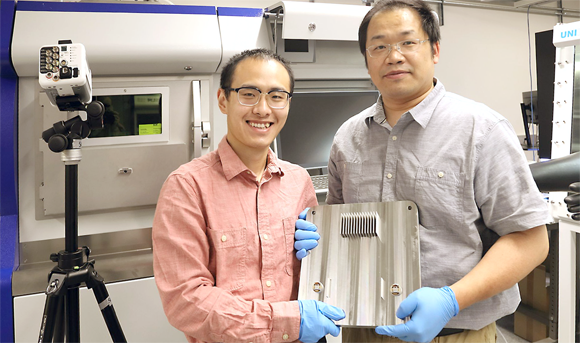

Lead by Tao Sun, associate professor of materials science and engineering at UVA developed a real-time keyhole detection method by integrating operando synchrotron x-ray imaging, near-infrared imaging and machine learning. This allows for the capture of thermal signatures associated with keyhole generation on a sub-millisecond basis and reputed 100% success rate. Utilising machine learning, the team also discovered two modes of keyhole oscillation.

“Our findings not only advance additive manufacturing research, but they can also practically serve to expand the commercial use of [PBF-LB] for metal parts manufacturing,” stated Anthony Rollett, co-director of the NextManufacturing Center at Carnegie Mellon University.

Sun concluded, “Porosity in metal parts remains a major hurdle for wider adoption of PBF-LB technique in some industries. Keyhole porosity is the most challenging defect type when it comes to real-time detection using lab-scale sensors because it occurs stochastically beneath the surface. Our approach provides a viable solution for high-fidelity, high-resolution detection of keyhole pore generation that can be readily applied in many Additive Manufacturing scenarios.”

The paper ‘Machine learning aided real-time detection of keyhole pore generation in laser powder bed fusion’ is available here.