Synchrotron X-ray techniques could lead to improved AM steel

October 29, 2021

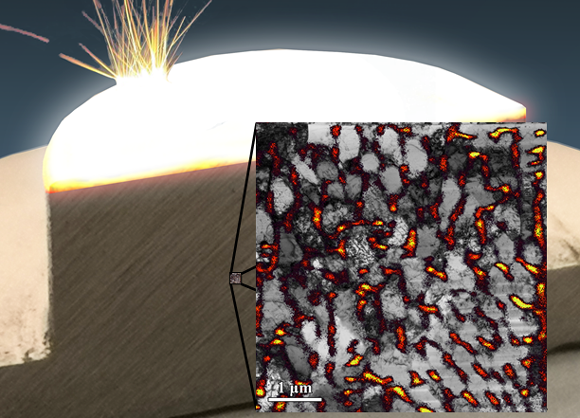

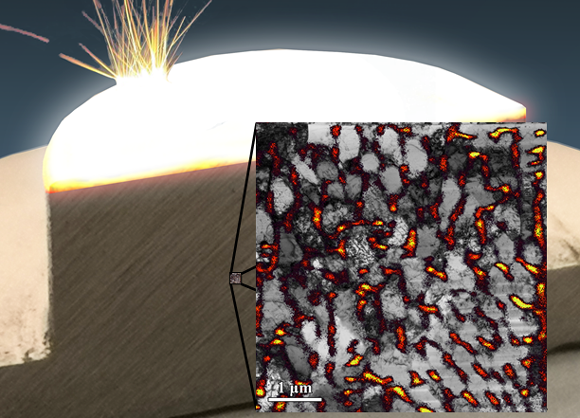

A new study led by researchers from Stony Brook University, New York, USA, researchers sheds light on the connection between the corrosion behaviour and underlying materials structure in additively manufactured 316L stainless steel using Laser Beam Powder Bed Fusion (PBF-LB) technology. Using multimodal synchrotron X-ray techniques, the team reported new connections between build parameters and the defect state in the material. This enables the researchers to map pathways for engineering an even better corrosion-resistant additively manufactured alloy.

The findings, published in the November issue of peer-reviewed journal Additive Manufacturing, could enable the future production of a highly corrosion-resistant stainless steel by engineering its defects at the nanoscale. The research also demonstrated that multimodal synchrotron techniques are becoming essential tools in establishing correlations between the AM process, underlying structure of the material and its realised performance.

“The major focus of our study was to understand the corrosion behaviour of laser additively manufactured 316L stainless steel in the context of microstructural defects that form due to the rapid solidification rates inherent to this 3D printing process,” stated Jason Trelewicz, co-author and associate professor of Materials Science and Engineering at the College of Engineering and Applied Sciences and the Institute for Advanced Computational Science, both in Stony Brook. “We show that while uniform surface corrosion of the printed 316L is similar to a traditional 316L alloy, the printed material exhibits an increased susceptibility to pitting, particularly in the samples with the greatest defect density uncovered from our synchrotron measurements.”

The team, consisting of research scientists and students in Professor Trelewicz’s group, the Engineered Microstructures and Radiation Effects Laboratory, working with collaborators at Brookhaven National Laboratory, conducted the synchrotron X-ray experiments at Brookhaven’s National Synchrotron Light Source II (NSLS-II) in Upton, New York.

The 316L samples were additively manufactured at the Pennsylvania State University by collaborator Professor Guha Manogharan. The team performed correlative electron microscopy at the Center for Functional Nanomaterials (CFN) at Brookhaven and corrosion measurements performed at Stony Brook University.

Beyond the development of novel additively manufactured materials, Trelewicz says the findings highlight the critical role correlative synchrotron X-ray and electron microscopy measurements can play in building a detailed picture of volume-averaged microstructural trends in materials developed by PBF-LB Additive Manufacturing.