Research project explores mass surface finishing for metal AM parts

May 18, 2020

A new case study published by surface finishing specialist Fintek, formerly Finishing Techniques Ltd, Bury, Lancashire, UK, focuses on a research project that explored mass surface finishing for additively manufactured parts. Sponsored by UK government agency Innovate UK, the research project was led by Croft Additive Manufacturing (CAM), with members including Liverpool John Moores University (LJMU), the Manufacturing Technology Centre (MTC) and Fintek.

As the study explains, when it comes to mass surface finishing additively manufactured components, a lack of qualified research and information leaves both AM part makers and mass surface finishing companies with little more than trial and error as a way of achieving the desired finish at a commercially viable cost. The research project was established to challenge this.

The AM challenge

The pace of development in equipment, materials and processes for Additive Manufacturing metal parts is rapid. However, mass surface finishing techniques have been struggling to keep up with this means of producing increasingly intricate and complex components.

Currently, the poor quality of surface finish of completed AM builds can make them unsuitable for some industrial applications. Post-processing, such as CNC machining or linishing of individual surfaces, is time-consuming and costly.

The problem is compounded by the fact that current mass surface finishing methods are optimised to subtractively engineered parts. Surface finishing alone can account for between40 and 60% of the cost of a completed AM component, an amount thatFintek notes would be intolerable for a subtractively engineered part.

Integrating Additive Manufacturing and finishing

The research project included two key research aims:

- Reduce the variability and overall surface roughness of an AM part by optimising the initial build parameters, and so make mass surface finishing more effective and quicker

- Improve mass surface finishing techniques to suit the increased part complexity of AM

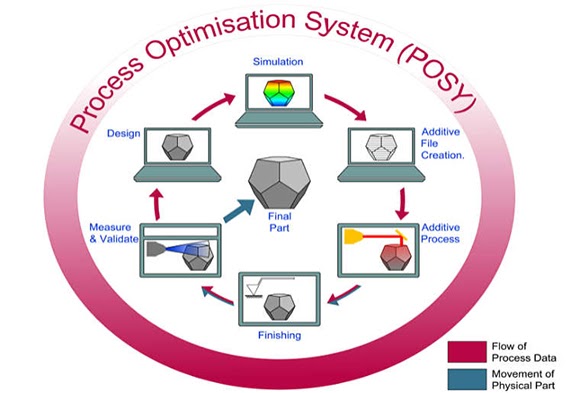

Meeting these two objectives will enable AM parts to achieve a comparable surface smoothness to a subtractively engineered component at a similar cost. Capturing process informatics from build and finishing stages, along with mechanical properties measured at key points, was vital to provide the data to develop a new process optimisation software tool (POSY).

POSY is being designed and developed by MTC. This will reportedly help Additive Manufacturers to predict and set the best build parameters to achieve near net shape while maintaining tensile strength and also reducing initial surface roughness. In addition, it will help AM part design teams to allow for the tolerances required by further post-processing using mass surface finishing techniques.

Developing meaningful benchmarks

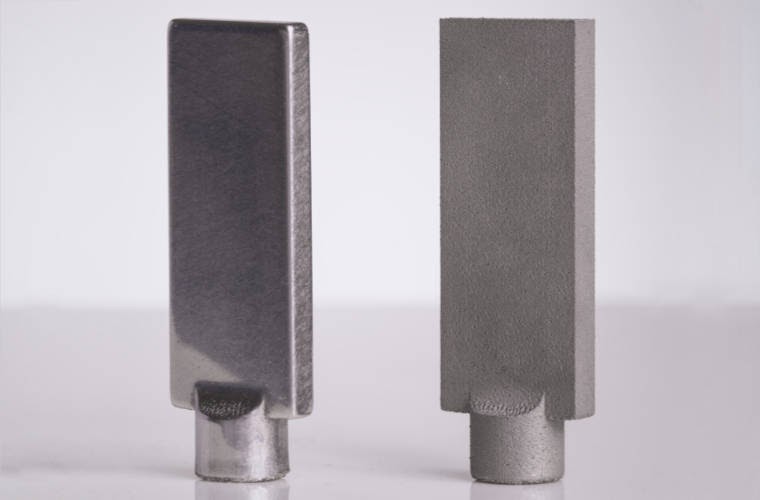

The MTC team helped to design the experimental project. At the outset, Croft additively manufactured simple test bars in stainless steel 316L, having defined a series of different laser parameters and build orientations. Surface roughness measurements for each set of parameters formed the basic data matrix to begin the POSY software development. This process was repeated to create a sizable database.

A set of test bars was also produced for mechanical testing by a team at LMJU, which also carried out further post-processing to surface finish the bars in both centrifugal disc and drag finishing machines. Additionally, an identical set of samples was provided to Fintek, which processed them in a centrifugal machine and a new generation high-energy stream finishing system, both designed and built by OTEC Präzisionsfinish GmbH. Measurements of surface roughness before and after processing, tensile strength and mechanical properties were then supplied to MTC to use in developing the process optimisation system.

In the centrifuge machine, LJMU found that roughness differed depending on if the AM bars were built layer-by-layer horizontally, vertically or at 45º. During the finishing cycle, they responded differently with plastic process media over time – vertical built bars saw the greatest reduction in surface roughness, followed by the horizontal build and then the 45º build as the cycle time increased. Drag finishing proved to be more aggressive over the same time scale.

Bespoke stream finishing to optimise process

Fintek found highly variable cycle times were necessary to achieve smoothing, and also discovered that the usual silicon carbide media used in high-energy stream finishing was unsuccessful, sometimes resulting in pitting on the AM part surface due to its grain structure.

Like LJMU, Fintek achieved better results using plastic media. Both LJMU and Fintek found that the greatest roughness decrease occurred in the first twenty minutes, with increments showing further improvement working up to eighty minutes of processing time at between 190 rpm and 250 rpm.

These initial studies also showed that the rate of material removal in post-processing had implications for the initial AM part build. The high-energy stream finishing performed best in achieving a commercially viable smoothness. However, as this process is capable of rapidly removing material, it would need to be mitigated by designing-in material to be added in strategic locations during the part build.

A more complex test part

The next series of tests represented a real-world additively manufactured component of greater shape complexity. With experimental design from MTC to help validate the POSY software, Croft created an AM part comprising a series of flat, curved, inner and outer surfaces. Again, initial surface roughness measurements and part build parameters were supplied to MTC for inclusion in POSY. Croft manufactured identical sets of test pieces for LJMU and Fintek to process, and the results from mechanical testing and high-energy stream surface finishing were added to the developing software tool.

To refine the stream finishing process, Fintek called on the laboratory facilities of OTEC Präzisionsfinish. With an adjustment of the plastic media, the SF machine proved capable of surface finishing external facets to Ra 0.05 µm in just twelve minutes – a time comparable to processing a subtractively engineered component and much more commercially acceptable. However, the smaller internal spaces were still challenging to penetrate for current process media types.

Validation of POSY

To validate the effectiveness of the data collated from the research and the new POSY software, a desired surface finish of an AM part was entered into the software tool, which then predicted the required build parameters and orientation necessary to achieve the target.

Built using this data, the AM part was tested and the actual surface roughness of the build was found to be within 6% of the software prediction. This demonstrated that by using POSY, a more accurate prediction of build parameters could be made to enable the creation of a part nearer to net shape from the first build, significantly reducing costly trial and error work often required. Just as important, the surface finish of the part was already much improved in the build, subsequently requiring less post-processing time.

Conclusion

With the help of Innovate UK, the partners of the research project believe that a leap forward has been made in understanding the correlation between AM build parameters and mass surface finishing. The benefits are more than just cost-saving; this new understanding alsoopens up areas of AM part application that are beyond current technology.

Further testing of AM materials and refinements of mass finishing media and processes are expected to provide a richer data set for the development of POSY. It is believed that this software tool will become even better at predicting the AM build parameters based on a target surface roughness and the known post-processing method. Importantly, stream finishing represents one of the newest forms of mass finishing. Being highly precise, adaptable and controllable, it is well suited to use with Additive Manufacturing in inline production processes.