Replique to launch RSure quality tracking module at Formnext 2022

October 5, 2022

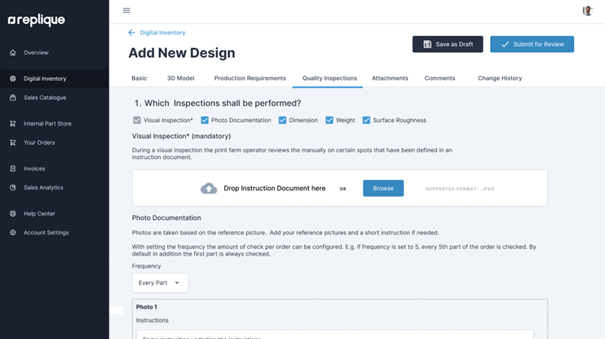

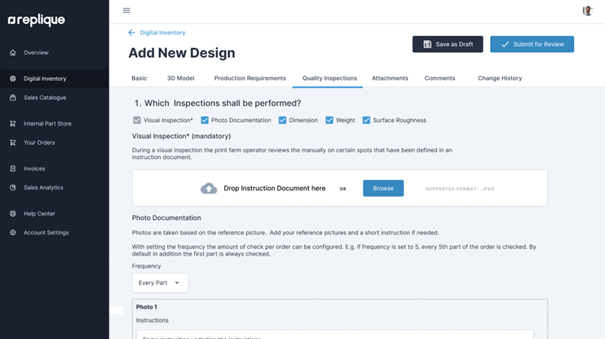

Replique, Mannheim, Germany, has reported that it intends to launch RSure, a tracking module that enables OEMs to track their additively manufactured parts directly, in an effort to ensure the final parts meet quality requirements. The module allows users to set quality specifications, undertake a digital inspection and trace parts being produced via Replique before the part is sent to customers.

RSure **also enables OEMs to include further quality checks for service bureaux to undertake on additively manufactured parts, including various certified measurements, functional tests and image upload to the OEM’s digital library on Replique. Via the secure platform, OEMs can access and view this information remotely at any time.

Formnext visitors will be able to test Replique’s encrypted ordering process – which is said to ensure that parts are additively manufactured in the required amount and quality – by ordering a free additively manufactured giveaway produced on-stand. This will also enable a look at the company’s digital inventory, which enables part designs to be stored, managed, and ordered internally.

Additionally, visitors will be able to hear about individual consumer and industrial customer application projects, including doorstopper for Alstom. This was qualified and manufactured with Forward AM using BASF’s metal filament Ultrafuse® 316L.

“As part of BASF, we know that industrial companies need standardised and repeatable production processes, especially when it comes to decentralised manufacturing,” stated Max Siebert, co-founder and CEO of Replique. “With our end-to-end solution we can ensure traceability, while providing repeatable quality and secure encryption of 3D printed parts.”

Replique’s solution works for both B2B and B2C companies and the use cases presented at Formnext cover just a small range of applications. The joint work with H. Gautzsch Company Group, in particular, is intended to demonstrate the Replique platform’s wide range of possibilities for internal and external ordering and fulfilment, as does the project with premium home appliance manufacturer Miele.

The new module will be on display at Booth B73, Hall 12.1.