Renishaw showcases metal AM implants to American Academy of Orthopaedic Surgeons

March 6, 2018

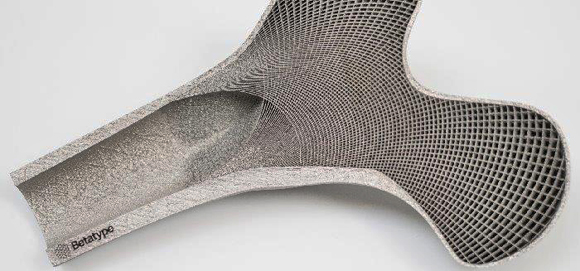

A prototype of a lattice-structured implant, designed by Betatype and additively manufactured by Imperial College London (Courtesy Betatype)

Renishaw plc is exhibiting a range of prototype metal additively manufactured orthopaedic implants at the American Academy of Orthopaedic Surgeons (AAOS) Annual Meeting in New Orleans, Louisiana, USA, March 6-7, 2018. The titanium prototypes have each been produced on Renishaw’s healthcare-optimised Additive Manufacturing systems, and will be used to demonstrate the results of the company’s UK government-funded project on the development of load-bearing lattice structures for orthopaedic implants.

Dr Jonathan Jeffers, Imperial College London, UK, is also presenting data from the ongoing project at the AAOS meeting. By incorporating a lattice into orthopaedic implants, the company states, implants can provide a scaffold structure for new bone tissue to grow into. The spacing and strut thickness of the lattice can be optimised to match the stiffness of surrounding bone. It may be possible to create a strain gradient on the bone which can accelerate growth.

“The partnership between Imperial College London and Renishaw is creating really exciting data on new materials that can control the way bone repairs itself,” commented Jeffers. “These materials could change the way orthopaedic implants are designed in the future, and certainly provide an opportunity to improve patient outcomes by repairing the musculoskeletal system with materials that can invoke the desired response in bone.”

The project has been carried out in collaboration with Betatype, London, UK, a design, engineering and materials science specialist for AM. According to Renishaw, Betatype has helped to optimise the design of titanium AM orthopaedic implants in order to deliver the most desirable features, quality and production speed for AM applications.

Ahead of the AAOS Annual Meeting, Sarat Babu, Betatype founder, commented, “On display at the show will be a portfolio of Additive Manufacturing builds to showcase what can be achieved on the Renishaw platform with Betatype capability. The builds include lattice structures which are more complex, in terms of resolution and density, than anything that can usually be achieved using traditional manufacturing techniques.”