Renishaw and nTopology collaboration produces intricate, pure copper structures

March 15, 2021

Renishaw, Wotton-Under-Edge, Gloucestershire, UK, has been working with software developer nTopology, New York City, USA, to demonstrate that, by using the right software and system in collaboration, intricate structures from copper are able to be additively manufactured.

Pure copper’s excellent thermal and electrical properties make it a highly-desirable material for heat exchangers and electrical components. While these properties are beneficial for end-user applications, they are what turn the process of Additive Manufacturing copper into a challenge.

The laser sintering of copper powder with an infra-red laser at a wavelength of 1070 nm is difficult, because, at that wavelength, copper is very reflective, allowing only a small amount of laser energy to be absorbed into the powder. Combining the high conductivity of copper and the laser energy required leads to instability, frequently resulting in the end part having poor mechanical properties.

Combining Renishaw’s RenAM 500S AM system and nTopology software, however, demonstrated an easy method for designing copper structures suitable for use in heat exchangers, as well as integration with Renishaw’s build preparation software, QuantAM.

A RenAM 500S system, with a single 500 Watt laser and 70 um laser spot size, was loaded with 99.9% pure copper powder, supplied by Carpenter Additive, Philadelphia, Pennsylvania, USA. The system was optimised to work with this material and was able to manufacture walls with a thickness of 0.35 mm and solids with a density over 98%, prior to heat treatment in 30 micron layers.

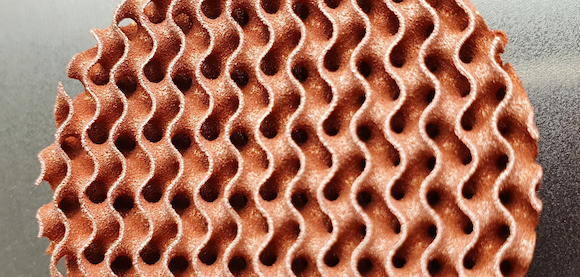

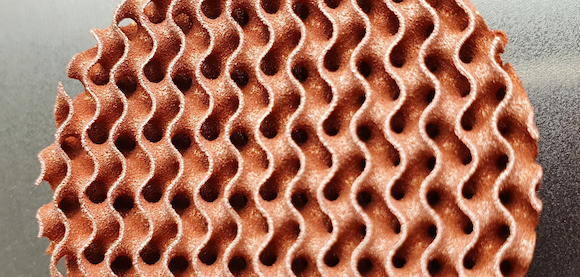

nTopology software was used to generate triply periodic minimal surfaces (TPMS) that are ideal for heat exchangers, which generally require the amount of surface area within a given volume to be maximised. The design criteria for the TPMS gyrold structure was for a wall thickness of 0.35 mm and cell sizes of 2 mm and 5 mm. The software was used to slice the design into 30 micron layers and export the boundaries and hatches as CLI files, replacing the traditional STL file format. These CLIs are imported into Renishaw’s QuantAM software to generate the build file for the AM process.

The AM system has now been delivered and installed at Cooksongold, a supplier of fabricated precious metals based in Birmingham, West Midlands, UK.

Ian Campbell, Industrial AM Program Manager at Cooksongold commented, “We are very encouraged by the initial work and results provided by Renishaw and nTopology. We look forward to using the machine to work on new customer applications for copper.”