Rapidia lowers cost of metal Additive Manufacturing machine and furnace package

March 20, 2023

Rapidia Inc, headquartered in Vancouver, British Columbia, Canada, has announced a significant reduction in the price of its metal Additive Manufacturing hardware, in an effort to make the technology more accessible. The company’s Conflux 1 system – consisting of a metal AM machine and vacuum sintering furnace – is now available starting from $99,000.

In 2020, Rapidia entered a partnership with ExOne, where ExOne marketed the platform as the ExOne Metal Designlab AM machine and X1F sintering furnace. This was a mutually beneficial arrangement, explained Rapidia, as it allowed access to ExOne’s established brand and distribution network, whilst expanding ExOne’s portfolio. When ExOne was acquired by Desktop Metal in late 2021, however, the partnership ended.

Since then, Rapidia has spent the last year building a sales team and network of their own. By controlling the entire customer journey, Rapidia states it is now able to deliver the Conflux 1 platform at a more accessible price.

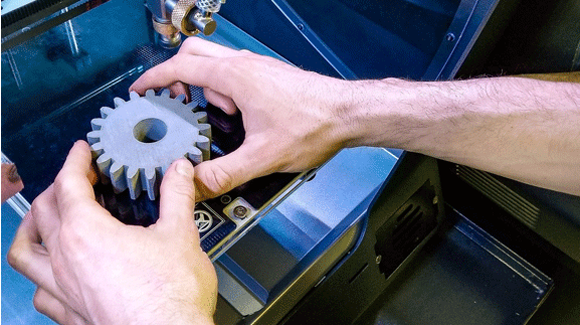

Rapidia’s two-step AM technology, developed over several years and first revealed in 2019, works by extruding a flowable bound metal paste. The paste is dried, layer by layer, creating green parts with 90% less binder than found in metal filaments or Metal Injection Moulding (MIM) feedstocks. As a room-temperature process, the technology is not limited by the speed of melting and then cooling polymer carriers. Moreover, the low binder content allows green parts to be put directly into short sintering cycles, skipping the debinding step and ultimately outputting many finished parts in under twenty-four hours.

“Our metal printing technology is accessible because of its ease of use and low operating cost,” stated Artem Bylinskii, CEO. “We’re now in a position where we feel we can be more proactive and more disruptive by making our technology more accessible in price too.”

Bylinskii adds, “We see a gap in metal Additive Manufacturing because the cost of entry for production solutions is so high. It’s a major risk for companies to borrow upwards of half a million to get that capability. With our new pricing, we hope to provide a more scalable production solution where businesses can start with a couple of machines, and then continue adding printers to their fleet at an easily digestible cost.”

Download Metal AM magazine