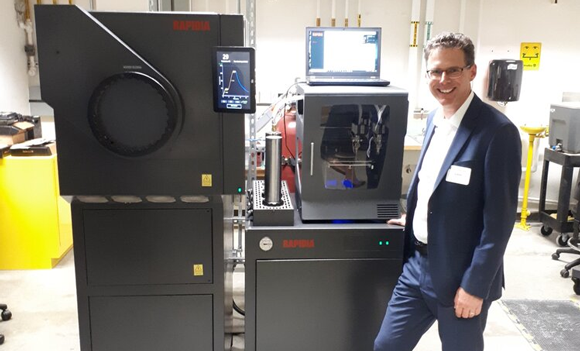

Rapidia begins shipments of its debinding-free bound-metal AM system

September 26, 2019

Rapidia Inc, Vancouver, British Columbia, Canada, has begun commercial shipments of its debinding-free bound-metal Additive Manufacturing system, with the first machine being installed at the Hatch Accelerator, a start-up incubator based at the University of British Columbia. The new Rapidia system will reportedly serve several start-ups located at the facility,

This news follows the first announcement of the Rapida system at Rapid+TCT in Detroit, Michigan, USA, in May this year. A number of further installations are said to be planned over the coming months.

The Rapidia system builds parts using a novel water-based metal paste AM process, followed by a sintering process. The use of water, instead of a typical binding element, eliminates a solvent-based debinding step and is said to result in a fast, simple to use system that is environmentally friendly and completely solvent-free.

The system is said to have several support modes, allowing complex internal structures, and can build components from CAD file to finished metal part, including sintering, in approximately twenty-four hours.