QuickBeam expands AM machine capabilities with series production of TiAl alloy

January 15, 2021

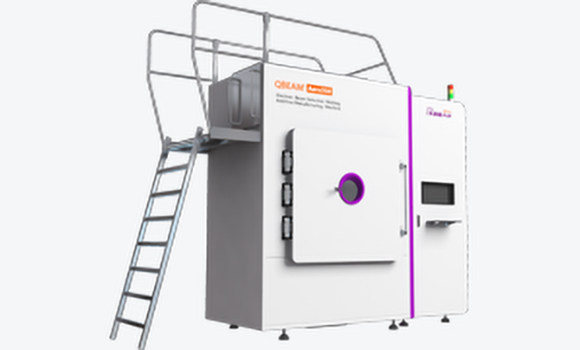

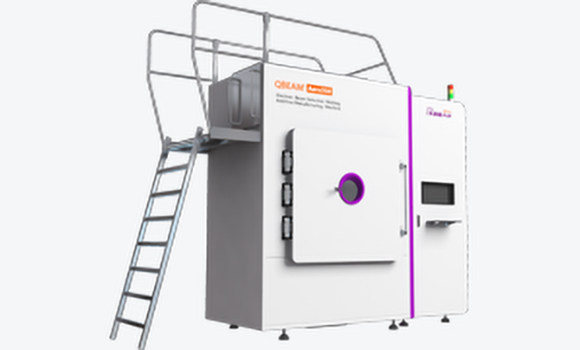

QuickBeam Tech. Co., Ltd., Tianjin, China, a developer of Additive Manufacturing machines, has announced it now offers series production of TiAl alloys. Established in 2015 as a Tsinghua University spin-out business, QuickBeam offers Electron Beam Powder Bed Fusion (PBF-EB) Additive Manufacturing machines, which includes its QBeamLab for R&D, QBeamMed200 for mass production of customised medical implants and QBeamAero350 for the manufacturing of large-sized components.

The company explains that the enhanced capabilities of its QBeamAero350 AM machine, including building dimensions, cathode service life and power supply, is opening up new opportunities to produce high-integrity parts larger and faster, in order to meet the increasing needs of large-size Additive Manufacturing components for aviation and aerospace.

The dimensions of the QBeamAero350’s build platform have reached 350×350×500 mm and the life of the cathode can be stabilised above 800 hours, with the development and application of LeB6 single crystal, which provides a prerequisite for the fabrication of large-size component and mass production.

The power of the electron gun has increased to 6 kW to maintain an adjustable building temperature from 600–1200 ℃, in order to cover a wide range materials such as titanium alloys (TC4, TA15), aluminium alloys (AlSi10Mg), copper alloys, superalloys (Inconel 718, Inconel 738, Inconel 939, MarM247), refractory metals (W, Mo), and TiAl intermetallic compound.

QuickBeam states its ongoing efforts with its AM technology has enabled the company to offer series production of metal components, which now includes TiAl alloys.

“EBSM [Electron Beam Selective Melting] helps us achieve the accuracy, complexity and functional integration we are striving for in the implant and aerospace industry,” commented Dr Guo, QuickBeam’s General Manager. “Our products and services are ready to fulfil our customers’ high expectations of generative design, good quality and high reliability.”