QuesTek launches high-performance stainless steel optimised for Additive Manufacturing

June 24, 2020

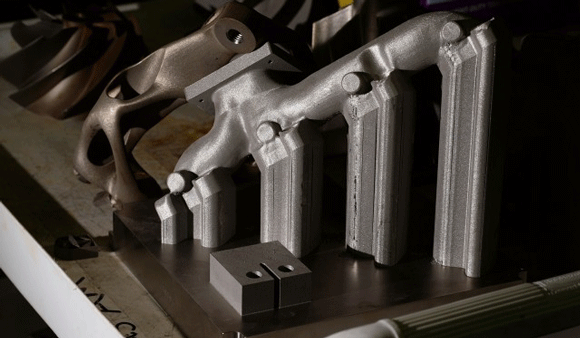

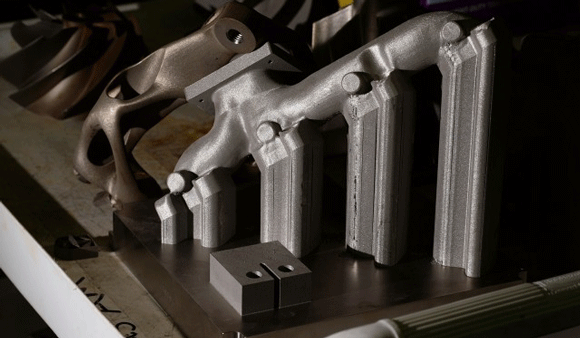

QuesTek Innovations LLC, Evanston, Illinois, USA, a developer of metal alloys and powders, has announced a new stainless steel composition for Powder Bed Fusion (PBF) Additive Manufacturing. Two variants of the new powder are available, QT 17-4 for use with a single low-temperature heat treatment, and QT 17-4+ for use in the as-built condition.

The development of the powder was funded by the US Navy Small Business Innovation Research programme and, according to the company, the new powder allows for the production of complex, high-strength stainless steel parts by AM which are comparable to wrought 17-4 PH, without the need for expensive cryogenic processing or high-temperature heat treatment.

The 17-4PH stainless steel commonly used in AM often requires higher-cost argon-atomised powder to be used to avoid retained austenite issues and the resulting poor properties; however, even the properties of argon-atomised 17-4PH fluctuate and are sensitive to the feedstock composition. The corrosion resistance and fatigue performance of the new alloy is said to be equivalent or improved over AM parts built using commercially available 17-4 stainless steel powders.

According to Dr Dana Frankel, QuesTek’s Manager of Design and Product Development, “With QuesTek’s QT 17-4 powders, a fully martensitic microstructure is achieved in the as-printed condition. The high-temperature solution heat treatment process required for conventional 17-4 is not needed for QuesTek’s alloys, and the resulting properties have less variation.”

The new 17-4 powders can be used in a wide range of industries, including aerospace, defence, medical, chemical processing and energy. Although QuesTek’s initial effort has focused on powder-based AM, it plans to demonstrate the new composition in one or more wire-based AM processes to enable larger component production at lower cost. QuesTek is reportedly in discussion with partners, including alloy producers, metal AM machine manufacturers and service bureaus, to license its technologies and accelerate commercial adoption.