PWR turns to Additive Manufacturing from Eplus3D for automotive cooling solutions

April 22, 2021

In 2019, automotive cooling systems provider PWR Performance Solutions, based in Queensland, Australia, began investigating metal Additive Manufacturing’s ability to allow the company to stay on the cutting edge of manufacturing.

PWR produces heat exchangers for all leading race categories – such as F1, NASCAR, V8 Supercars, Deutsche Tourenwagen Masters and World Rally Championship – as well as automotive, aerospace and military applications; as such, it made sense to test this key component against AM’s abilities.

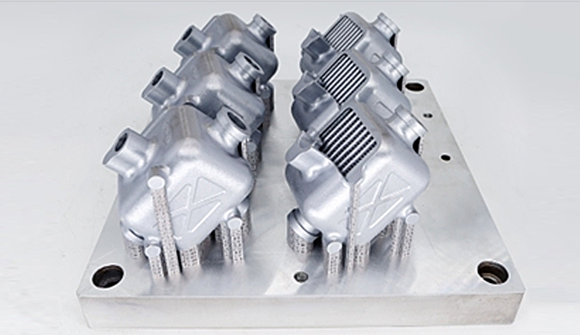

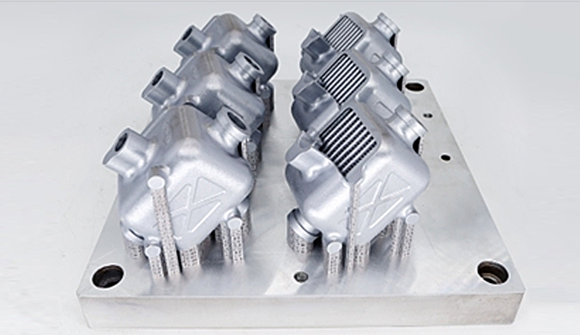

To test various aspects of AM, PWR engineers designed a heat exchanger with a fin structure and tube array as a benchmark to test the minimum wall thickness, surface finish and heat transfer efficiency. The additively manufactured parts, provided by several metal AM suppliers, were compared against one another, with PWR deciding the Eplus3D Laser Beam Powder Bed Fusion (PBF-LB) machine EP-M250Pro produced the best results.

Heat exchangers and radiators are important in industrial equipment for temperature control: it allows heat to be transferred from one fluid to another, in turn allowing the piece of equipment to operate at the temperature it was designed to be most efficient at, preventing damage caused by overheating. Most radiators are made of aluminium because of its light weight, high usability and good thermal conductivity.

The traditional manufacturing method involves brazing many separate pieces to form a ‘core’, which would then have tanks formed and welded to it; this is a complex manufacturing process with many stages and processes. The geometries of these radiators can be limited by this production process to relatively simple forms, but metal AM offers manufacturers the opportunity to change the design and production of radiators radically.

Typically, heat exchangers and radiators are linear, rectangular, tubular, or shell design; because of this, it can be challenging to package within available spaces. AM offers the ability to fit heat exchangers into irregular spaces, often smaller and lighter than the convention, with the same performance. AM also allows several parts to be fabricated in one piece, which reduces the amount of welding required and, hence, possible leak paths.

Perhaps at the foremost of AM’s abilities to improve heat exchangers is its ability to allow for the better regulation of temperature with the ability to produce small, complex channels, thus allowing engineers to design larger internal heat transfer areas. In conjunction with simulation tools, this allows optimised designs to be realised which are not possible via traditional manufacturing techniques.